100% Original Equipment For The Production Of Beer Keg - 3HL, 5HL, 10HL Micro brewery turnkey system – Alston Detail:

General description

Capacity: 3HL 5HL 10HL Or 5BBL 10BBL Micro Brewery Turnkey System.

Heating method: Steam (recommended), Direct fire, Electric element.

Obtainable productivity of beer, including the natural loss during technological processes (for reference only):

Note: Brewery performance depends on the quantity of the Cylindrical-Conical Tanks (CCT) and beer production time.

Equipment Description

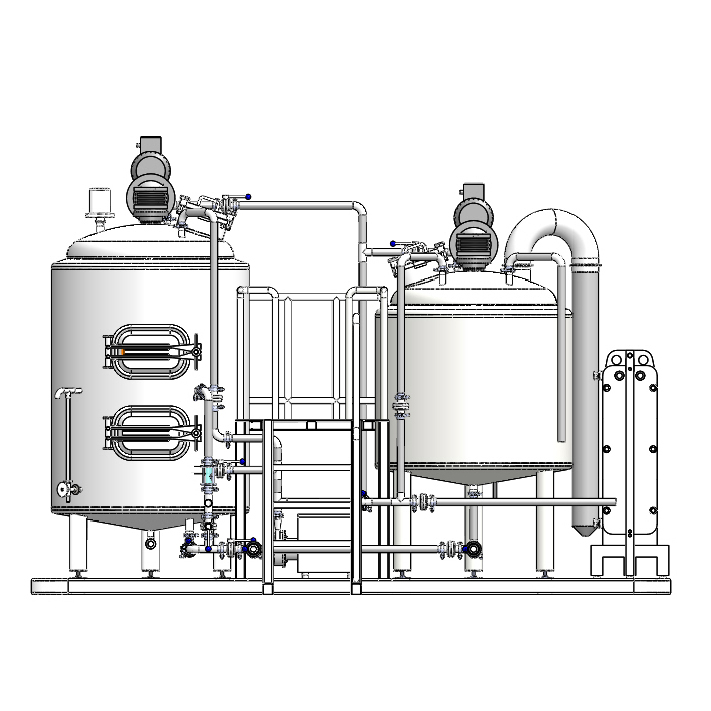

1.Brewhouse

Standard Setup

● Mash / boiling tank with top stir, paddle type mixer. VFD, with steam condensing unit

● Lauter / whirlpool tank: Upper lauter tun, with top stir, VFD, lower whirlpool tank with tangent wort inlet

● Support fittings: double / single stage plate cooler, piping strainer, grist hydrator, wort sink etc

● Standard brewhouse platform or customized

● All pump & Stir with VFD

● With hot water tank configured for sparging and mashing in etc, and increase the production efficiency.

● Valves to be manual butterfly one or pneumatic

● Piping connection to be TC or DIN.

Features

● Mash boiling tank combined for decoction brewing

● To stir with shaft connector to lower the twist force

● Natural filter by gravity and get more clear wort

● Well adjusted temp and water blending unit for better grain and water mixing

● Special tank and piping construction to avoid the wort aeration problem and decrease the material lost

● Special designed steam condensing unit, with both steam condensing and water heating function

● Brewhouse automation with possible upgrading.

● The whole system can be installed on platform for easy removing and installation

2.Fementation tank

All tanks are made by sanitary SS304 material, which meet domestic and international food safety and hygiene standard.

They are cylindrical cone bottom tank, the cone is 60-72degree for exhaust the yeast easier. The external are made by 2B stainless steel drawing board, connected by welding.

The internal pickling passivation treatment, and equiped with 80mm polyurethane insulation.

The tanks with dimple cooling jacketon cone and cylinder, they are cooled by glycol water or alcohol water.

Also the glycol inlet is seperated control according to volume of tank.

Type: Double Layer Conical Tank

Volume: 300L, 500L, 1000L and 2000L. (Support Customized).

Accessories:

● Top Manway or Side Shadow less Manway

● Racking Port with Tri-Clover Butterfly Valve

● Discharge Port with Tri-Clover Butterfly Valve

● 2 Tri-Clover Outlets with Butterfly Valves

● CIP Arm and Spray Ball

● Sample Valve

● Pressure Gauge

● Safety Valve

● Thermowell

NOTE: If you want to customize any of our standard sets of brewing equipment, all you need to do is to send us your request.

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" is the persistent conception of our firm for the long-term to create jointly with consumers for mutual reciprocity and mutual reward for 100% Original Equipment For The Production Of Beer Keg - 3HL, 5HL, 10HL Micro brewery turnkey system – Alston, The product will supply to all over the world, such as: Toronto, Finland, Amsterdam, With good quality, reasonable price and sincere service, we enjoy a good reputation. Products are exported to South America, Australia, Southeast Asia and so on. Warmly welcome customers at home and abroad to cooperate with us for the brilliant future.

Good quality, reasonable prices, rich variety and perfect after-sales service, it's nice!

-

2022 wholesale price Beer Canning Equipment - ...

-

Super Lowest Price Micro Brewing Beer Equipment...

-

Top Suppliers Beer Maker - 3BBL,5BBL,7BBL Com...

-

Hot sale Large Beer Brewery Equipment - 20HL-5...

-

2022 wholesale price Mixing Tank - 20BBL Jacke...

-

2022 China New Design Small Beer Brewery Equipm...