5-15BBL Brewing System

Brewhouse is designed and fabricated as the exact brewing process request from client and the local requirement. Tanks size designed as exact beer plato / gravity from client. The goal is helping client with easy brewing operation, making the whole brewhouse setup more suitable for right recipe , increasing the efficiency and lowering the energy cost etc.

Brewhouse:

2 vessel: Mash/Lauter tank+Kettle/Whirlpool

3 vessel: Mash Lauter tank+Brew Kettle+Whirlpool

Brewhouse Features

1.Brewhouse Feature:

● Higher wort extract.

● Lower energy cost and material consumption.

● Well adjusted temp and water blending unit for better grain and water mixing.

● Higher efficiency steam jacket to increase heating efficiency and lower energy consumption.

● Special tank and piping construction to avoid the wort aeration problem and decrease the material lost.

● Special designed steam condensing unit, with both steam condensing and water heating function.

● Adopting advanced world famouse brand components to ensure the smoothly running.

● Support different heating way, steam, direct fire and electric, depending on site and local utility costs.

● High-quality stainless steel material 304 or 316 and exquisite appearance.

● Brewing vessel and fermentation tanks are tested prior to shipment to avoid on-site repairs, guarantee uninterrupted startup and assured vessel performance.

2.Fementation tank

● All tanks are made by sanitary SS304 material, which meet domestic and international food safety and hygiene standard.

●They are cylindrical cone bottom tank, the cone is 60-72degree for exhaust the yeast easier.

●The external are made by 2B stainless steel drawing board, connected by welding.

●The internal pickling passivation treatment, and equiped with 80mm polyurethane insulation.

●The tanks with dimple cooling jacketon cone and cylinder, they are cooled by glycol water or alcohol water.

●Also the glycol inlet is seperated control according to volume of tank.

3.Cooling system

Basic configuration:

Matching: Chiller, Glycol Liquid Tank, Pump, Piping lines.

Capacity: according to brewery size.

Following our special design&production on piping lines and tanks, the advantage on configuring skill, we have more preciously temp control and the reasonable energy consumption during beer production process. As the part with big energy consumption, the reasonable configuration affects the energy consumption, with the top brand compressor and reasonable piping net works design and pump etc, the whole system is with stable running.

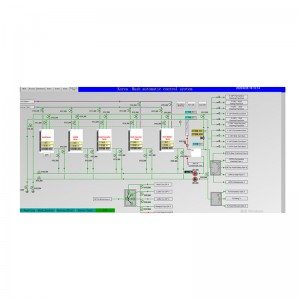

4.Control system

Control system uses intelligent central system which is developed for beer and beverage production industry, combined with positive innovation based on the previous experience, and the improvement on brewing process.

Our control system is well related with other units of whole brewing plant, all PLC control interface the assorted piping and valves etc following the reasonable operation of most of the brewmasters. The interface is simple but clear enough, flowchat perfectly follow the exact request.

As the request of modernize brewing process renovation and future possible development, we keeping upgrading on our PLC software, meanwhile we are establishing stabe partnership with famous software company to design the programming to meet our brewing process, that will helps to make our brewing system with real automatation.

| No. | Item | Equipment | Specifications |

| 1 | malt milling system | Malt miller machineGrist case (optional) | The entire grain milling unit from outside silo to inside mill, receptacle, premasher and so on |

| 2 | Mash system | Mash tank, | 1.mechanical Agitation: With VFD control, at the top horizontal motor with seal.2.Steam venting chimney with anti backflow pipe.3.Condensate recycle to hot water tank. |

| Lauter tank | Function: lauter, filter the wort.1.Sparging pipe for grain washing with TC connection.2.Wort collecting pipe and back washing device to cleaning false bottom.3.Mechanical Raker: VFD control, gear motor on the top.4.Spent grain:Automatic raker device, Grain removing plate with reverse, forward is raker, reverse is grain out.5.Milled false bottom: 0.7mm distance, diameter designed suitable for the lauter tun, with dense supporting leg, detachable handle.6.Wort circulation inlet TC on top with elbow and mash inlet upon false bottom on side wall.7.Side mounted spent grain port .8.With discharge hole, thermometer PT100 and necessary valves and fittings. | ||

| Boiling Whirlpool tank | 1.Whirlpool tangent pumped at 1/3height of the tank2.Steam venting chimney with anti backflow pipe.3.Condensate recycle to hot water tank. | ||

| Hot water tank (optional) | 1.Steam Jacket heating/direct gas fired heating/electric heating2.Sight gauge for water level3.With SS HLT pump with variable speed control | ||

| Mash/wort/hot water pump | Transfer the wort and water to each tank with frequency control. | ||

| Operation pipes | 1.Material: SS304 sanitary pipes.2.Sanitary stainless steel valve and pipeline, Easy to operate and reasonable in design;3.Wort inlet at side of tank to reduce the oxygen. | ||

| Plate heat exchanger | Function: wort cooling.1.Two stage and six flow, hot wort to cold wort, tap water to hot water, glycol water recycle.2.Design Structure: Suspension type, screw material is SUS304, nut material is brass, easy disassembled for cleaning.3. Stainless steel 304 material4.Design pressure:1.0 Mpa;5.Working temperature:170°C.6.Tri-clamp quick-installed. | ||

| 3 | Fermenting system(Celler) | Beer fermenters | Jacketed Conical fermentation tank for beer cooling, fermenting and storage. 1.All AISI-304 Stainless Steel Construction2.Jacketed & Insulated3.Dual Zone Dimple Cooling Jacket4.Dish Top & 60° Conical Bottom5. Stainless Steel Legs with Leveling Ports6.Top Manway or Side Shadow less Manway7.With Racking arm, Discharge Port, CIP Arm and Spray Ball, Sample Valve, Shock proof Pressure Gauge, Safety Valve, Thermowell and Pressure regulator valve. |

| 4 | Bright beer system | Bright beer tanks (optional) Yeast adding tank Accessories, such as sample valve, pressure gauge, safety valve and so on |

Beer maturation/conditioning /serving/filtered beer receiving.1.All AISI-304 Stainless Steel Construction2.Jacketed & Insulated3.Dual Zone Dimple Cooling Jacket4.Dish Top & 140° Conical Bottom5.Stainless Steel Legs with Leveling Ports6.Top Manway or Side Shadow less Manway7.With Rotating Racking arm, Discharge port, CIP Arm and Spray Ball, Sample Valve, Shock proof Pressure Gauge, Safety Valve, Pressure regulator valve, Thermowell, Level sight, Carbonation stone. |

| 5 | Cooling system | Ice water tank | 1.Insulated conical top and sloped bottom2.Liquid level sight tube for water level3.Rotating CIP spray ball |

| Refrigerating unit Ice water pump |

Assembly unit, wind cooling, enviromental refrigerant: R404a or R407c, compressor and electrical part meet UL/CUL/CE certification. | ||

| 6 | CIP cleaning system | disinfection tank & alkali tank &cleaning pump etc. | 1).Caustic tank: Electric heating element inside, with anti-dry device for safety.2).Sterilization tank: Stainless steel vessel.3).Control and pump:Portable sanitary CIP pump, SS cart and controller. |

| 7 | Controller | Control system: | PLC automatic and semi-automatic, the elements brand include Schneider, Delixi, Siemens and so on. |

| Optional | |||

| 1 | Steam distributor | For steam transfer | |

| 2 | Condensate water recycle system | Condersate wanter system recovery to cleaning. | |

| 3 | Yeast tank or propagation | Yeast storage tank and propagation system. | |

| 4 | Filling machine | Filler machine for keg, bottle, cans. | |

| 5 | Air compressor | Air compressor machine, dryer, CO2 cylinder. | |

| 6 | Water treatment system | Water treatment equipment | |