Now we finished the production of 1000L brewery project and ready to delivery, excited to see our friend receiving that.

Here let we see the details of 1000L brewery system.

1.Malt milling machine with double roller.

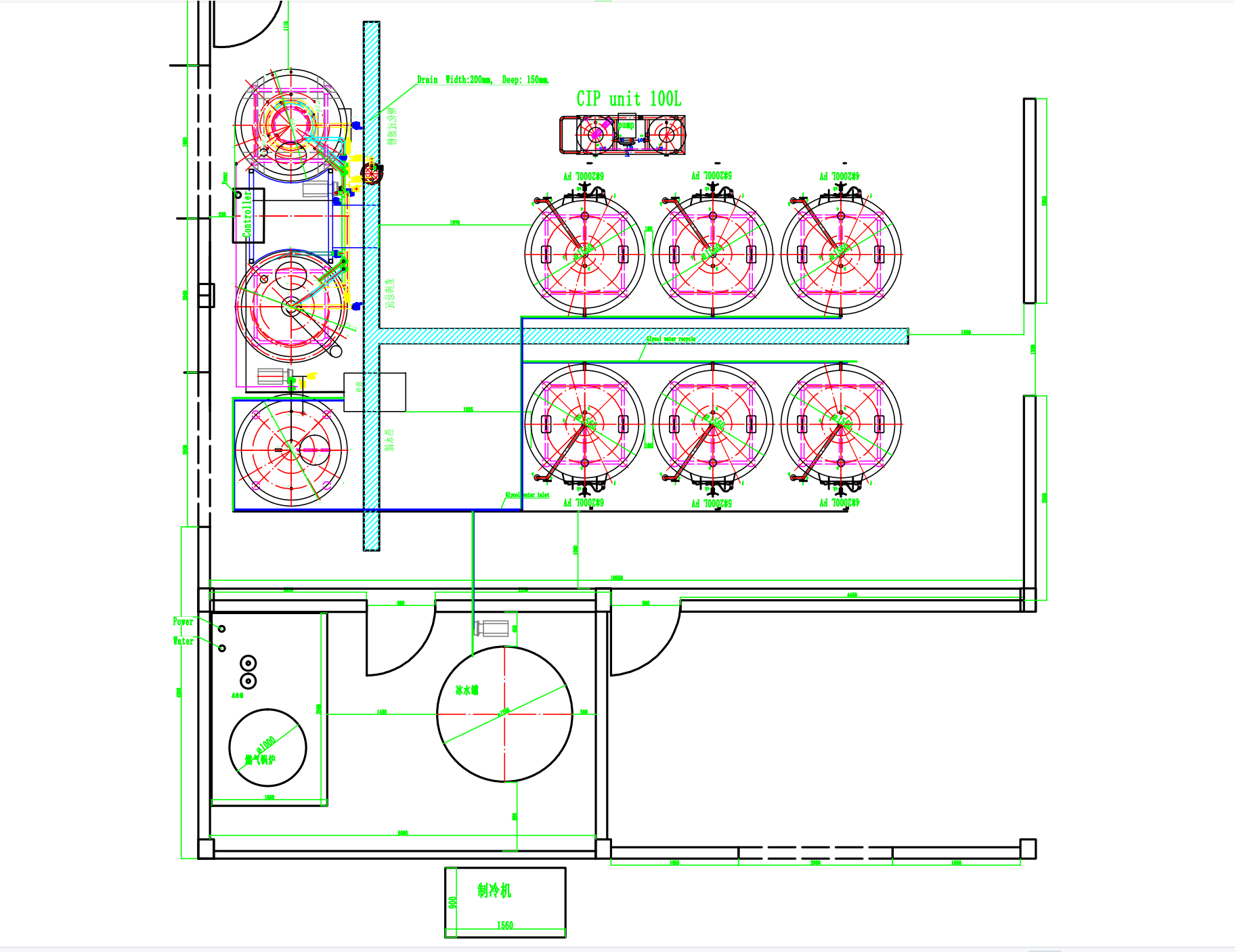

2.1000L 2 vessel brewhouse: Brewhouse section is the most important part of the whole brewery system., which is directly related with the wort and beer quality.

The modular design saves time and cost of installation and commissioning.

-Mash Lauter tank with steam heating for improving the brewing efficiency.

-Brew kettle can boiling with pressure for high land area.

-Platform: compact design with detachable Platform with adjust screw leg.

-Condensate recycle to cooling.

|

||

|

|

|

|

|

|

3.Fermenter and unitank:

-6 sets of 20HL fermenters.

-The fermenters fabricated by ASTE company following the more reasonable craft beer brewing request and clients special request.

-Our cellar tanks are produced by stainless steel 304, all tanks fits requirement of PED certification. All fittings using the top level Chinese supplier, the stable standard on quality is priority.

-Finished the glycol pipes line in factory for easy installing.

|

|

||

|

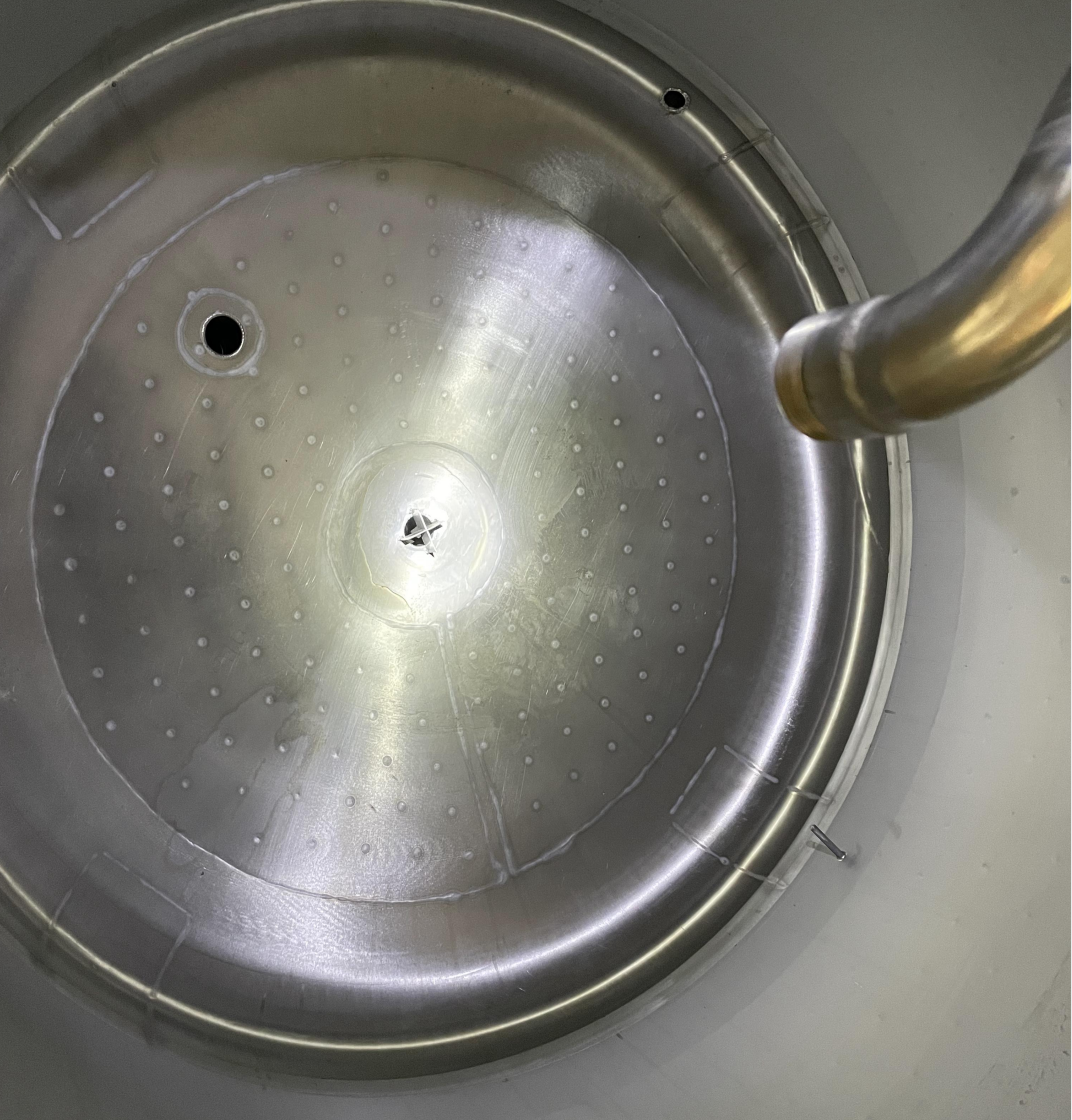

Inner surface of fermenter |

Racking arm |

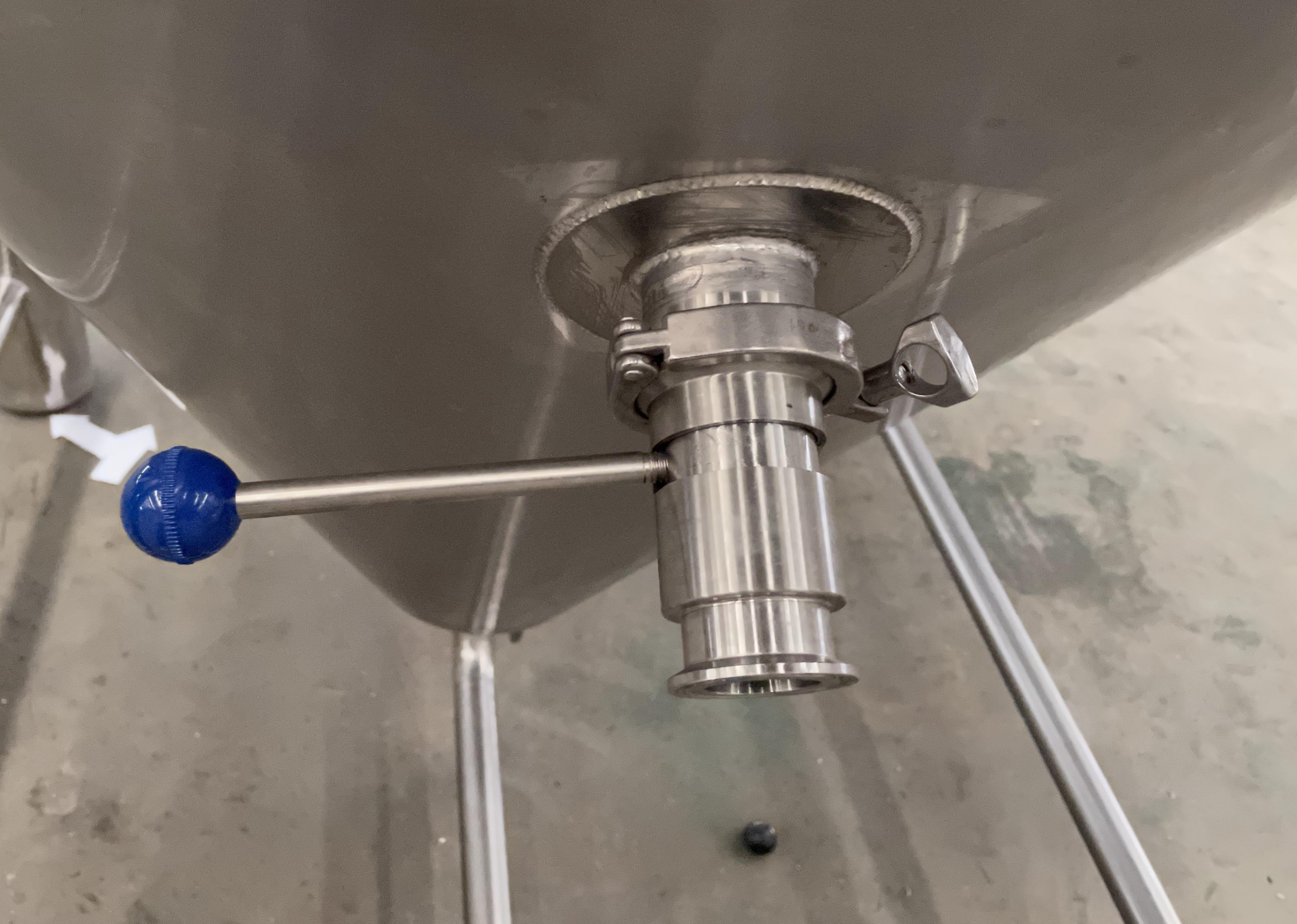

Pressure regulator valve |

|

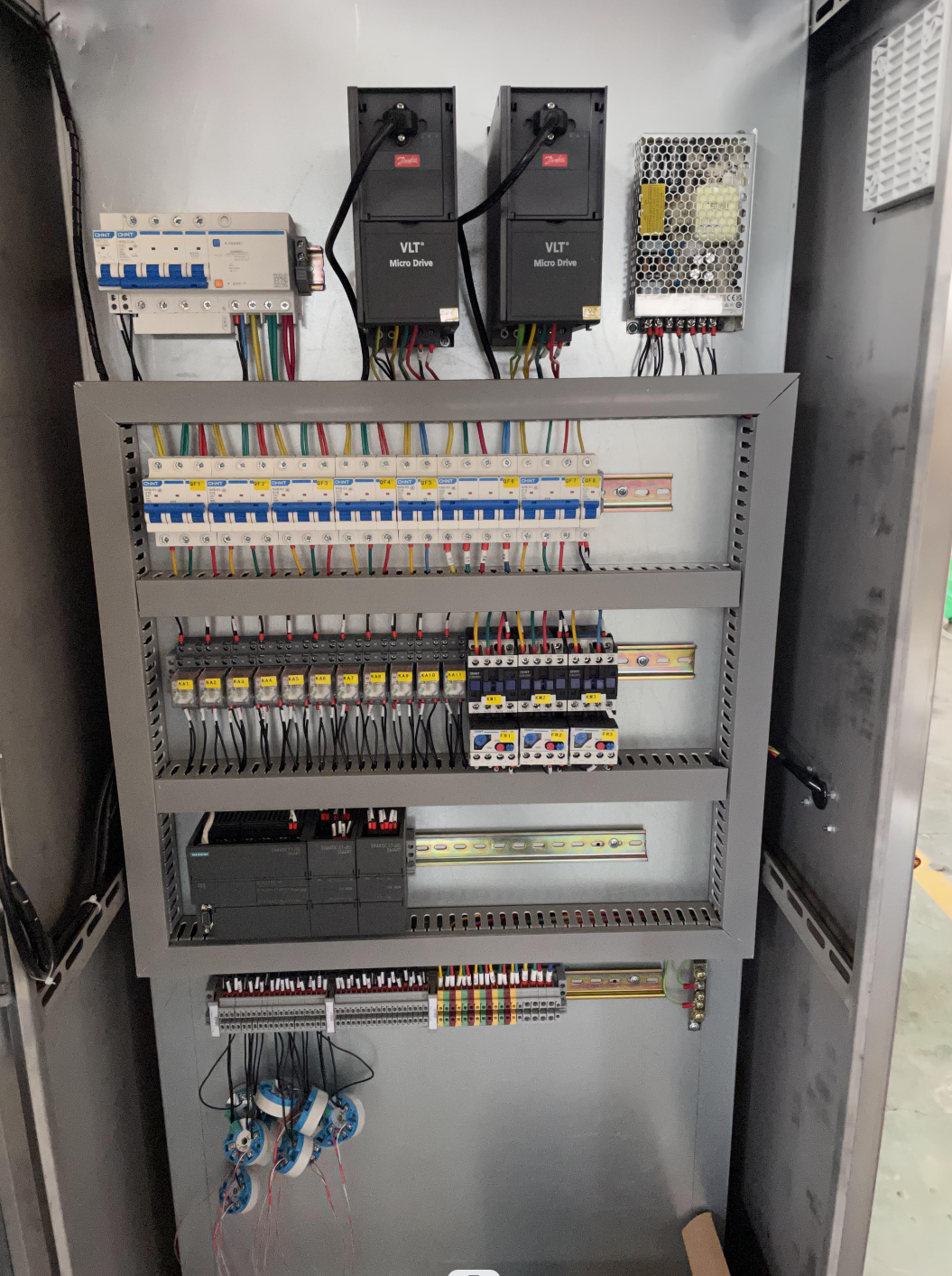

4.Control panel

-PLC brewhouse controler and Digital fermenters controller.

-The control system from ASTE adops the basic standard of food&beverage production industry, combined with positive innovation based on the previous experience and the improvements on brewing process.

-The temp setting and control of mash, boiling, hot water, fermenters, etc is achieved by the interface on PLC touch screen or controller, which fits the different request from production.

|

Brewery controller on Platform |

Controller system |

In order to save the placing on brewery, we set the control cabinet on brewhouse platform.

After 2 month they will start to installing according to the drawing, hope everything goes well at his side.

Let’s we see it.

Cheers!!

Post time: Dec-05-2022