Description

Capacity: 30HL-50HL or customized

Heating method: Steam

Efficiency: 8-12 Brews per day

Advantages

●Labor Savings: With automation handling many of the tasks previously done by hand, breweries can operate with fewer staff.

This can lead to significant savings in labor costs. Furthermore, staff can be reallocated to other areas of the business, such as sales, marketing, or customer service.

●Efficiency Boost: One of the primary advantages of an automated brewing system is its efficiency.

By automating many of the brewing process's manual aspects, these systems can produce more beer in less time, optimizing production schedules and increasing the volume of saleable product.

●Resource Savings: Through precise measurements and control, automated systems can lead to savings in raw materials, energy, and water.

This not only reduces costs but also minimizes waste, making the brewing process more sustainable.

●Consistent Quality: In the brewing industry, consistency is crucial. Fans of a particular beer brand expect the same taste, aroma, and mouthfeel every time they crack open a bottle.

Automated systems, with their precise control over ingredients, temperatures, and timings, ensure that every batch matches the previous one in terms of quality.

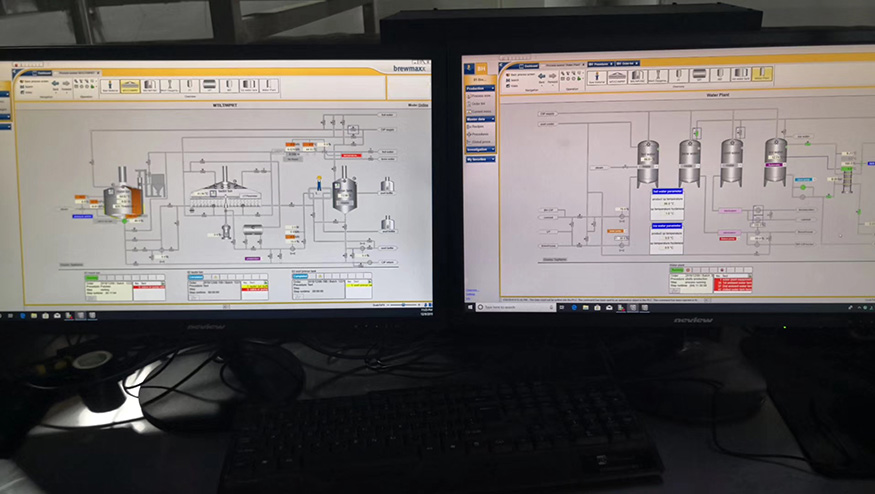

●Real-time Data Monitoring: Modern commercial automated brewing systems come equipped with various sensors and analytics tools.These tools provide brewers with real-time data about the brewing process, enabling them to make informed decisions and quickly address any issues that may arise.

Function

Brewhouse control:

A commercial automated brewing system is a technologically advanced solution designed to simplify and optimize the brewing process on a commercial scale.While traditional brewing methods require a lot of manual labor and precision, these modern systems streamline the process using automation and sophisticated technology.There are a few essential components of these systems:

&Control Panel: This is the brain of the operation. With touch screen interfaces, brewers can easily adjust settings, control fermentation temperatures, and more.

&Automated Mashing: Instead of manually adding grains, the system does it for you. This ensures consistency in every batch.

&Temperature Control: Precise temperature control is crucial in brewing. Automated systems provide accurate temperature regulation throughout the process.

Historically, brewing was a meticulous and labor-intensive process.The introduction of automation in brewing has not only simplified the process but has also made it more consistent, ensuring that every batch of beer tastes the same.

One of the primary benefits of using an automated brewing system is the reduction in manual errors.For instance, over-boiling or incorrect temperatures can adversely affect the beer's taste. With automation, these risks are significantly minimized.

The use of commercial automated brewing systems is now widespread among modern breweries, aiming to meet growing demand, ensure product consistency, and streamline their operations.

Features

•Commercial automated brewing systems have revolutionized the way beer is produced on a large scale.These systems are equipped with numerous functionalities designed to make the brewing process more efficient, consistent, and scalable.

•Mashing: One of the most critical steps in brewing is mashing. The system automatically mixes the grains with water at the right temperature.This process extracts the sugars from the grains, which will later be fermented into alcohol.

•Boiling: Post mashing, the liquid, known as wort, is boiled. Automated systems ensure that this boiling occurs at the precise temperature and duration required for the specific beer being produced.

•Fermentation Monitoring: The fermentation process can be finicky. Too warm or too cold, and the entire batch can be ruined.Automated systems continuously monitor the fermentation tanks, adjusting the temperature as needed to ensure optimal yeast activity.

•Cleaning and Sanitization: After brewing, the equipment needs thorough cleaning to prevent contamination of subsequent batches.Automated systems come with integrated cleaning protocols that ensure every part of the system is cleaned and sanitized efficiently.

•Quality Control and Data Analytics: Advanced systems now integrate sensors that monitor various parameters during brewing.These data points are crucial for maintaining consistency across batches and for continuous improvement.Additionally, real-time data analytics can alert brewers to any issues immediately, allowing for swift interventions.The automation of these functions not only ensures a higher quality of beer but also allows breweries to operate more efficiently, reducing wastage, and increasing profitability.