Description

According to the different fruit wine’s raw material, we can get the juice with prosper elements through targeted raw material processing, and you can choose squeezing juice before fermentation or after fermentation.

Process before fermenation: fruit pre-treament including sorting, cleaning, crushing, squeezing juice clarification and juice improvement, etc.

1. Raw material sorting anc cleaning

Sorting: please choose the maturity fruit as raw material

Cleaning: Washing before squeezing raw material is imprtant measure to reduce pollution, and it’s much important for squeezing with skin. Therefore, we have to wash the sediment and impurities on the pericarp with fluid water. If necessary, clean with water after rinsing the raw material by potassium permanganate solution.

1-1. Grape vibration (grain) separator

The machine is designed with French lechnology. It adopts high-frequency vibration principle lo make materials move straight.

The conveying plate is equipped with two sieve plates and a hopper. The machine can remove impurities automatically.

It's surface is sandblasted, suilablc and elcganl.

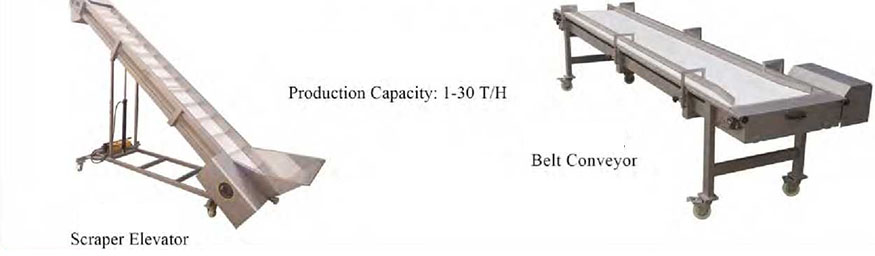

1-2. Auxiliary Grape Processing Equipment

These machines are mainly used for material horizontal conveying and lifting, as supporting equipment for production line. The belt is made of food grade PVC, frame adopts 304 stainless steel and sandblasted.

Simple and bcaulifiil appearance!

1-3. Screw pump

Peristaltic pump: used to transfer wine between tanks and the whole grapes to the lerineinalion umk. Low speed working, small damage to the grapes and low dissolved oxygen rate.

2. Crushing, Destemmer

Crushing process demands every fruit ruptures broken, but the seeds and stem can’t be crushes, or the oil esters, glycosides substance and some substance of stem in the seed will increase the bitterness of the wine. The pulp and stem should be separated immediately after crushing, to prevent the green class taste and bitter substance of stem dissolve out. Crusher includes double roll crusher, drum scraper crusher, cerntrifugal crusher, hammer crusher, etc.

The series of press are suitable for squeezing juice from fermented grapes and other materials with high fiber content.

Features:

Twin screw press with low speed, high juicing rate.

The pressure of slag plug is adjustable, material humidity is adjustable. The frame and parts in contact with materials are all stainless steel.

3. Residue andjuice separation

The juice flows out by itself without pressing after broken is called artesian juice, and juice flow out after pressing is called pressed juice.

Artesian juice is in high qualiy, should used to ndependent fermentation to make high -quality wine. The broken fruit should be pressed in twice. At the first, increase the pressure gradually to press and let the huice out as much as possible, but the quality of juice is lower, it’s hould be brewed separately, and also can mixed with artesian juice. Loosen residue, add water or not to pressing for second time. Pressed juice has heavy mixed flavor and low quality, which should be used for distilled liquor or other usage. The device generally is continuous screw-type pressure.

The machine is designed and manufacuired by German technology.

Features:

High pressure, Quick and clean juice separation, Stable performance.

Applications: Il can be applied to press grapes (ice grapes) and berries such as apple, mulberry, sirawberry and kiwi fruil to juice.

Maximum working pressure is 2bar, and the mcmbrancc is imporicd from Germany

4. Juice transfer pump

Flexible Impeller Pump and Lobe Pump