High definition Equipment Beer - Brewery Manual control system – Alston Detail:

Advantages

● Reduction in labor

● Improved beer quality and consistency

● Automatic brewhouse temperature, material flow, and temperature control of your cellar tanks (fermentation tank, brite beer tank, etc)

● Energy Recovery

● System configuration for a link to Internet

● Automatic access to production and equipment communication

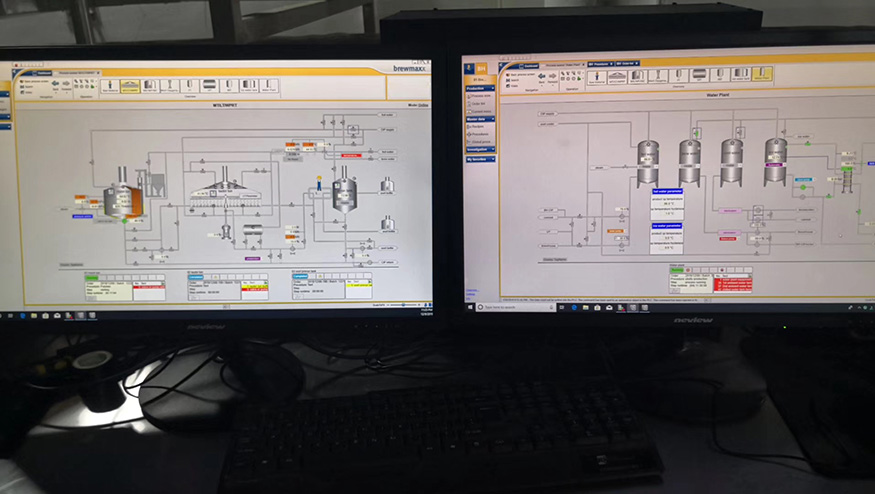

Our programming team has streamlined automatic control systems for efficiency and easy operation. Over the last ten years, we have built up an excellent relationship with the Rockwell & Siemens systems operation division.

Also we can offer CE, UL, and CUL certified control cabinets with electronic elements suitable for customers all over the world.

With this automated control system, you can monitor working conditions on your smart device as long as you have access to internet.

Monitor

● Pressure

● Temperature

● Cellar tanks – glycol tank, fermenters, brite beer tanks, etc.

Function

Brewhouse control:

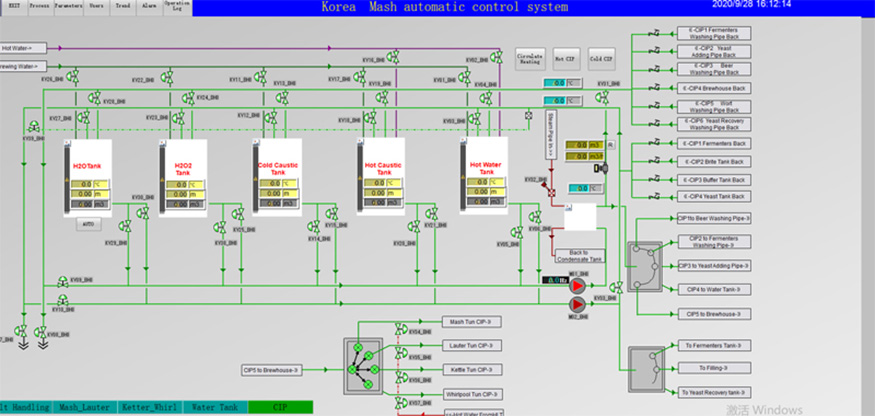

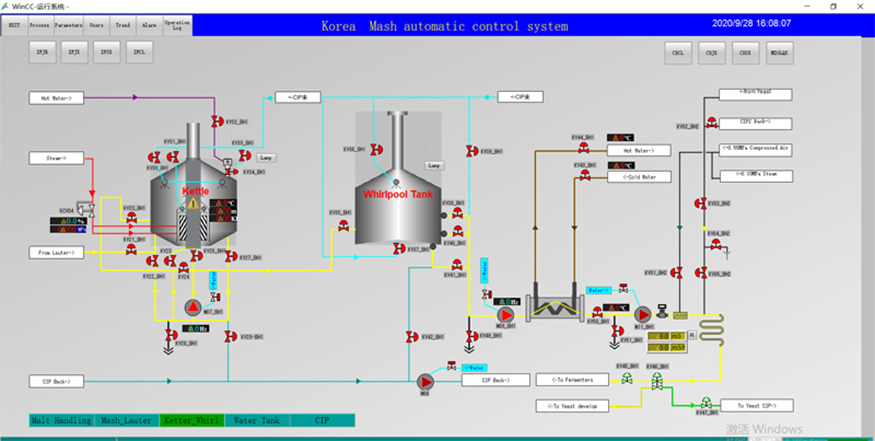

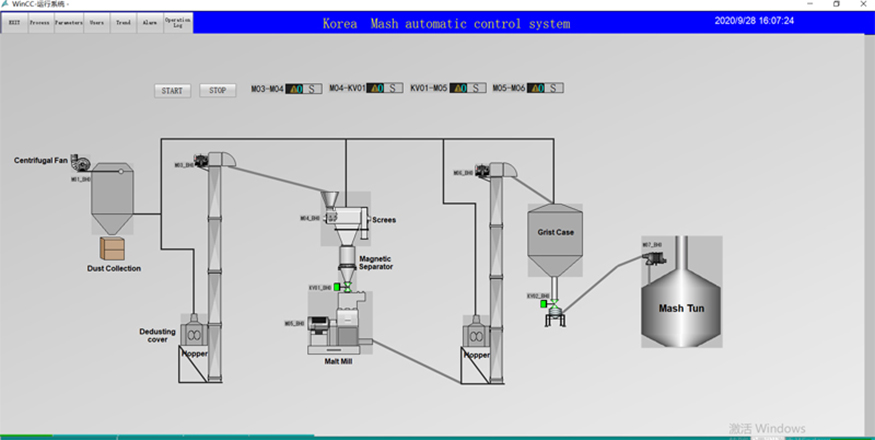

The saccharification control system is pneumatic valve control (using industrial control machine for control).

1. The temperature of the mashing pot is fully automatic.

2. The turbidity of wort in the filter tank is detected by a turbidity meter.

3. The steam heating of the boiling pot is controlled by a thin-film steam regulating valve, and the valve opening can be adjusted to control the amount of steam.

4. Saccharification pots and filter tanks are equipped with liquid level switches, and boiling pots, rotary sinks, cold water and hot water tanks are all equipped with electronic level gauges.

Fermenter’s control:

● Ice water tank and cold water tank temperature display.

● Control fermentation tank temperature.

● Control glycol pump frequency converter and motor.

● Control cooling system temperature.

● Temperature is controlled by solenoid valve.

● Temperature self-control.

Product detail pictures:

Related Product Guide:

The pretty loaded projects management experiences and one to a person support model make the high importance of business enterprise communication and our easy understanding of your expectations for High definition Equipment Beer - Brewery Manual control system – Alston, The product will supply to all over the world, such as: Germany, Austria, Muscat, Our product quality is one of the major concerns and has been produced to meet the customer's standards. "Customer services and relationship" is another important area which we understand good communication and relationships with our customers is the most significant power to run it as a long term business.

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!

-

100% Original Equipment For The Production Of B...

-

Super Lowest Price Micro Brewing Beer Equipment...

-

Cheap price Beer Brewing Equipment 30l - Brewe...

-

Super Lowest Price Micro Brewing Beer Equipment...

-

Super Lowest Price Micro Brewing Beer Equipment...

-

Hot-selling Beer Brewing Equipment Micro Brewer...