High Quality Beer Filling Equipment - Microbrewery Beer Canning Line – Alston Detail:

Description

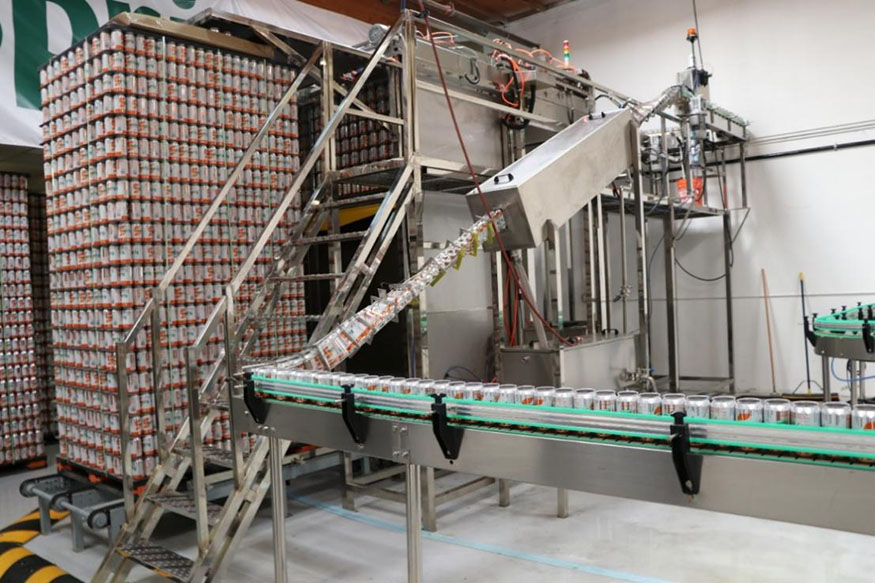

This linear beer canning line is used for filling beer in cans, rinser, filler and seamer are separated unit. It can finish all the process such as washing, filling and sealing.

It adopts isobaric filling principle and filling valve adopts high precision mechanical valve. It has advantages of fast filling speed, high precision in liquid level and ensure that it only starts to filling when there is a can, otherwise it will stop. Using the device structure of filling valve precover device plus supporting can bottom device, it can guarantee the maximum stability of cans when they passing in and out. Filling cylinder braces use worm-gear box going up and down to satisfy cans of different height. Float switches in the filling cylinder ensure a smooth liquid inlet state.

Whole process

Beer brewery–can washing—beer canning–seaming–pasteurizing tunnel–can dryerdate printer–carton packing machine/shrink wraping machine.

According to your brewery, then we can provide you 1000-8000cans filling line per hour.

Part 1: 1500CPH aluminum canned beer canning line

| Item | Machine description | Model | Size | Power | Qty. |

| mm | kw | ||||

| 1 | Automatic aluminum can de-palletizer | XD-1 | 7500*3200*3700 | 7kw | 1set |

| 2 | Tunnel type can washer | XG-1 | 1500*500*2500 | 0.37kw | 1set |

| 3 | Monobloc 2 in 1 carbonated drink canning-seaming unit | BCGF12-4 | 3000*2100*2000 | 5.5kw | 1 set |

| Inlet conveyor | FS-1 | 2m | 1 set | ||

| Belt conveyor | SYS-1 | 2m | 1 set | ||

| Arm controller | AC-1 | / | 1set | ||

| Lubrication system | / | / | 1set |

Part 2: 1500CPH Aluminum Canned beer Packing System

| Items | Machine description | Model | Power | Size(mm) | Qty. |

| 1 | Warming tunnel (9m length, 1m belt width) |

YFP-9 | 10kw | 9000*1300*1780 | 1set |

| Plate heat exchanger and steam control system | / | / | / | 3sets | |

| 2 | Bottle dryer | YFC-1 | 7.5kw | 1500*670*1800 | 1set |

| 3 | Can turning device (500ml) |

FG-500 | / | 500mm length | 2sets |

| 4 | Automatic PE film shrink wrapping machine | 10packs/min | 26kw | 5050*3000*1600 | 1set |

Machine description

Part 1: 1500CPH 500ml beer canning machine

1 Option, Automatic aluminum can de-palletizer

1. The purposes and principles.

Automatic des-tacking machine is mainly suitable for the whole crib tin (cans) automatic destacking empty cans, it will be stacked on the pallet empty cans, bottom-up layers of ascension and layered pushed to the path of the conveyor chain, with empty cans of spray cans machine use, replace artificial row of cans and traditional empty cans of unloading tank machine, can save a lot of artificial, increase production capacity.

2. Monobloc 2 in 1 beer canning-seaming machine

Part 2: Aluminum canned beer packing system

1. Warming pasteurizer tunnel

Description

The principle is: Conveyor brings bottles into the cooling tunnel, there will be cooling water generated from side holding tanks to spray by spray nozzles on the top of tunnel onto passing bottles. With heat exchange principle, the bottles temperature will be low down to normal room temperature to increase product shelf time.

The water tank temperature zone will be finalized according to capacity request. The pump system will send water in and out.

All body material is high quality SUS304; The transportation is by engineering plastic chain.

2. Bottle dryer

1. This machine is mainly used for the drying outside of bottles before or after the processing that the machine requires the bottle without water outside.

2. This type of machine adopts advanced technology of air knife, can work at low temperature, featuring stable performance, high visibility and fine drying effect. And it is suitable for the production line of medium & high speed.

3. The air knives of the machine can be adjusted in any direction and the drying area can be adjusted according to the actual needs. All the operations are very easy.

4. This type of machine is suitable for various shapes of bottles. There is no secondary pollution resulted from brush, free of maintenance.

5. Low energy consumption. Each heating fan can be controlled separately according to the actual conditions and it is the ideal drying machine in all wine packing lines.

5. Automatic PE film shrink wrapping machine

Technical parameter

● Facility type: WD-150A type

● Facility external size: L5050×W3300×H2100mm

● Wrappage max size: L600×W400×H350mm

● Shrinkage film size: PE, PVC, POF

● Shrinkage thermo thickness: 0.03-0.15mm

● Thermo shrinkage tunnel temperature: 160 – 260°can adjust at will

Product detail pictures:

Related Product Guide:

Sticking towards the theory of "Super Good quality, Satisfactory service" ,We are striving to become a superb business enterprise partner of you for High Quality Beer Filling Equipment - Microbrewery Beer Canning Line – Alston, The product will supply to all over the world, such as: Bandung, Angola, Honduras, All styles appear on our website are for customizing. We meet up to personal requirements with all products of your very own styles. Our concept is to help presenting the confidence of each buyers with the offering of our most sincere service, and the right product.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.

-

2022 China New Design Small Beer Brewery Equipm...

-

China wholesale Beer Brewery Equipment - Comme...

-

OEM/ODM China Micro Beer Brewing Equipment - F...

-

2022 High quality Diy Beer Brewing Equipment -...

-

Chinese Professional Bright Beer Tank - Stainl...

-

2022 High quality Diy Beer Brewing Equipment -...