Proposal Analysis&recommendation

Firstly Thanks for the kind patience on the communication on this brewery project, we hope we had something helpful for you.

This documents if basically for explaining you more about us and our possible plan for your brewery setup, we hope this helps with more interest and confidence on us, that we can be a good partner of perfect brewing solution.

- Regarding automation, we are the only one why can do real automation on brewing system compared with all others in Jinan area. The partners we are working together for automation is Brewmaxx from Proleit, and the other team who has more than 20 years of experience and engineering background in Proleit. I do believe the automation is such an important part to guarantee a successful brewery.

- We are the company who can offer you real turnkey plant, which means we do all design, fabrication, installation, commission as the whole package.

- Regarding the our way of making any brewery, all based on the exact brewing request, this is part of the content that we hope learn more from you while meeting or you visiting us one day. The more details about your beer and brewing process or habit etc, the better we can make the brewery. There are different preference and habit from different brewmasters, this is a big and important concern for a successful brewery setup.

Generally: We are the option that can bring you really reliable quality and also at reasonable investment. And we are not only selling you the materials, more importantly is the solution to guarantee every smooth brew, that you can save as much labors as you can, also you make full use of materials, energy etc.

And there is never the case that you buy anything at cheapest price but the highest quality, but we believe we can be the best choice for you, looking forward to your further interest and taking further on the coming weeks/months.

Chapter Two:

Based on the proposal, quotes and other necessary documents, I have the further analysis want to share with you as below, which is based on your exact brewing process request, and finally we have there can be a start of art brewery from our team and you do all brews as you wish.

Pls note this is based on our engineering background, there might be something that with your different idea, we can talk further on the topics that you disagree, it will be a great honor to have further comments from you:

In General:

After reading the info about your beers, we suggest to make the whole plant, especially the brewhouse part based average plate of 15 degree, which means you get finally 20HL wort/beer output of max 15 plato from each brew. This request approx 459kg malts from each brew (basic malt consumption)

1.Grain handing:

1.Firstly we recommend to have a good mill, the recommendation is to order the mill from Europe. We know quality and working conditions of the ones in Chinese market. The point is with a good malt mill bring better milling effect, you have basically yield efficiency increase of 4-5%, which is for each brew.

2.Besides there should be a grist hopper for malt storage, the hopper can be for milled malt storage of min 2 brews. (There is load sensor configured and combined with automation for good weight load control)

3.The malt transport unit is suggest to be two units as below:

- One is for connection between mill outlet and hopper inlet.

- The other one for connection between hopper outlet to mash tun pre masher.

4.Based on this the brewer can choose to prepare milled malt before brewing day, or do the malt milling of the second brew in the same day while the first brew is processing.

5.As we noticed you need the whole automatic setup, everything recommended above is combined with system automation.

2.Brewhouse unit:

Part One: Basic design basis

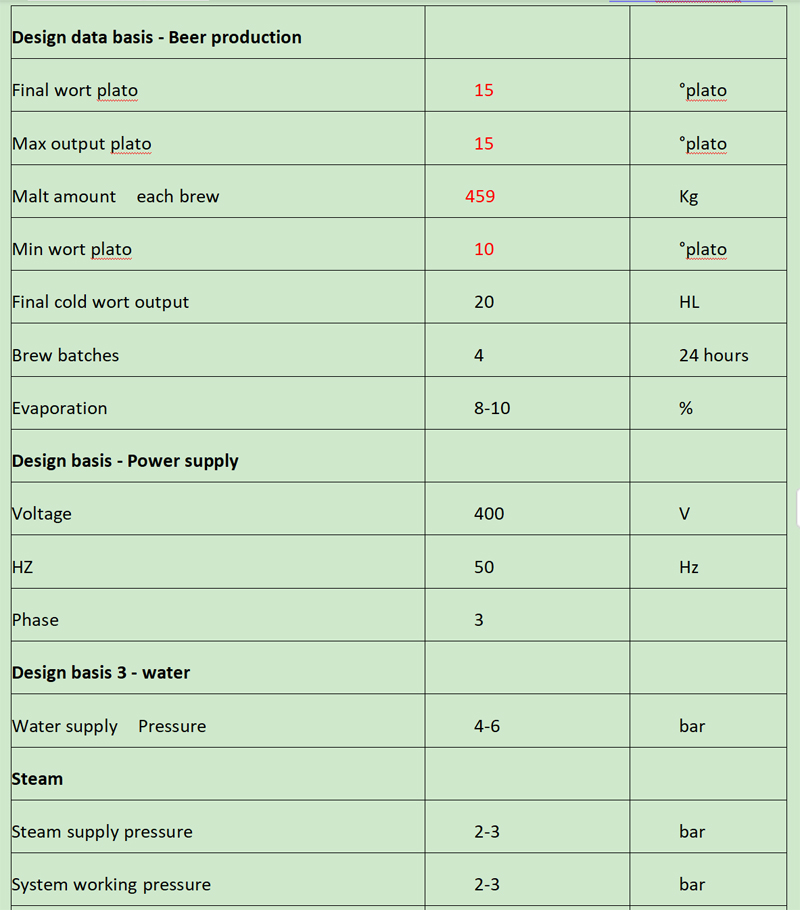

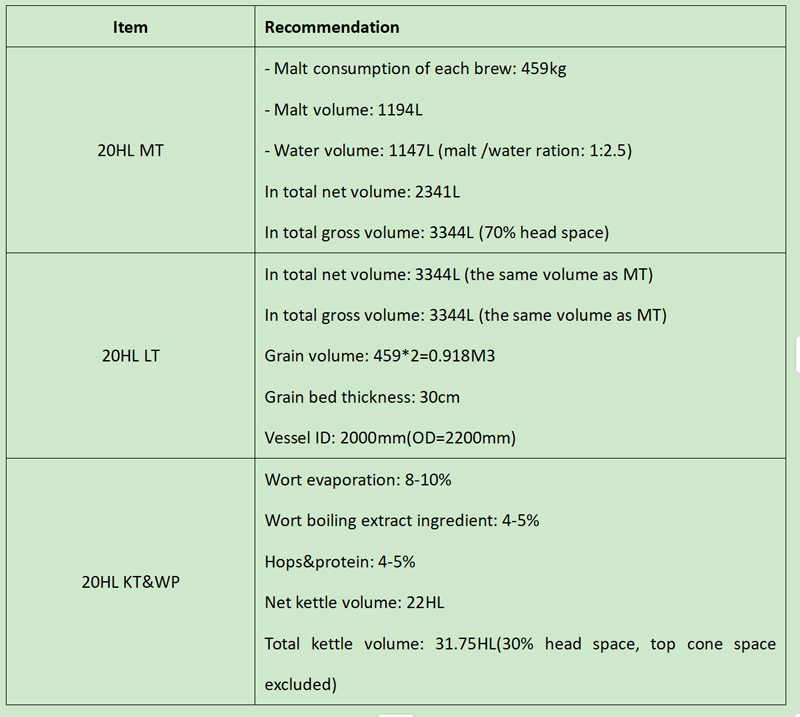

Firstly based on the basic beer spec, we suggest to do do the brewhouse design based on having the final cold wort output of 20HL at 15 plato after each brew. Below is the basic calculation that we recommend you, also the way that we proceed with your brewhouse design:

Part Two: Brewhouse flexibility

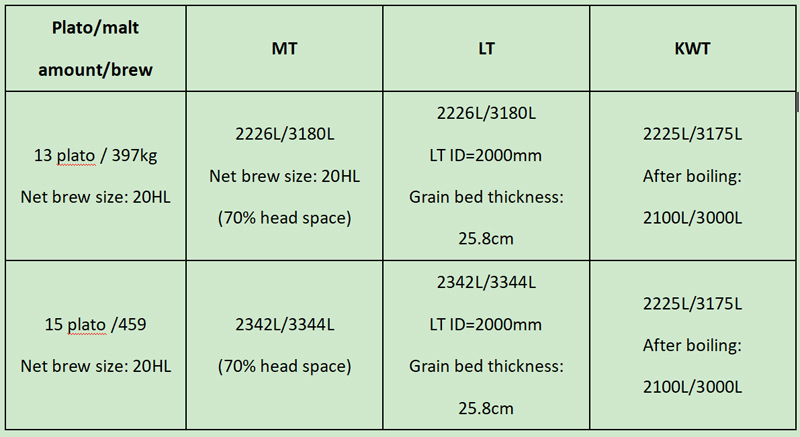

Since we have big range based on the output wort/beer plato, the flexibility on brewing size and capacity as below:

Remarks:

- Based on analysis above, we can have the brewhouse volume covers the full range of your beer plato.

- Pls note the analysis is based on the consumption of basic malt, others malts for different special brew not in the consideration, but the head space of each vessel is sufficient for different recipes.

- The key part is the lauter tun, as we know the grain bed thickness is the most important, who is related with brewing quality and efficiency etc. Based on the average 20HL brew size, we think the grain bed thickness of 25.8cm still works for lauter tun, or you think about to increase the brew size a little bit. Based on the higher plato of 16, we have grain bed thickness of 30-32cm, we assume this is mostly for your special beer, and this still works as we see, if you are ok to have the lautering time a little longer.

Part Three: Brewhouse efficiency

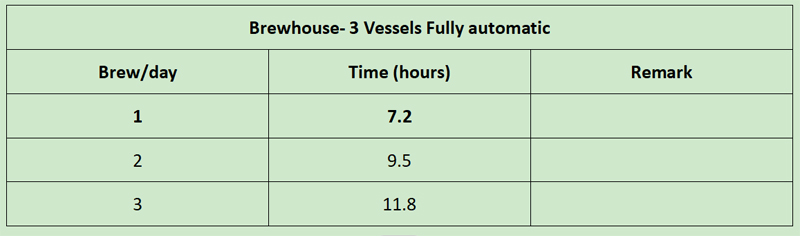

Since we will need the brewhouse also with good efficiency, I have the basic analysis of brewing time as below, hope this works.

There is one thing under guarantee: A 3 vessel automatic brewhouse is sufficient enough for supporting 3 brews per day. If there is other request like rice cooker, syrup additive, this need to be discussed further.

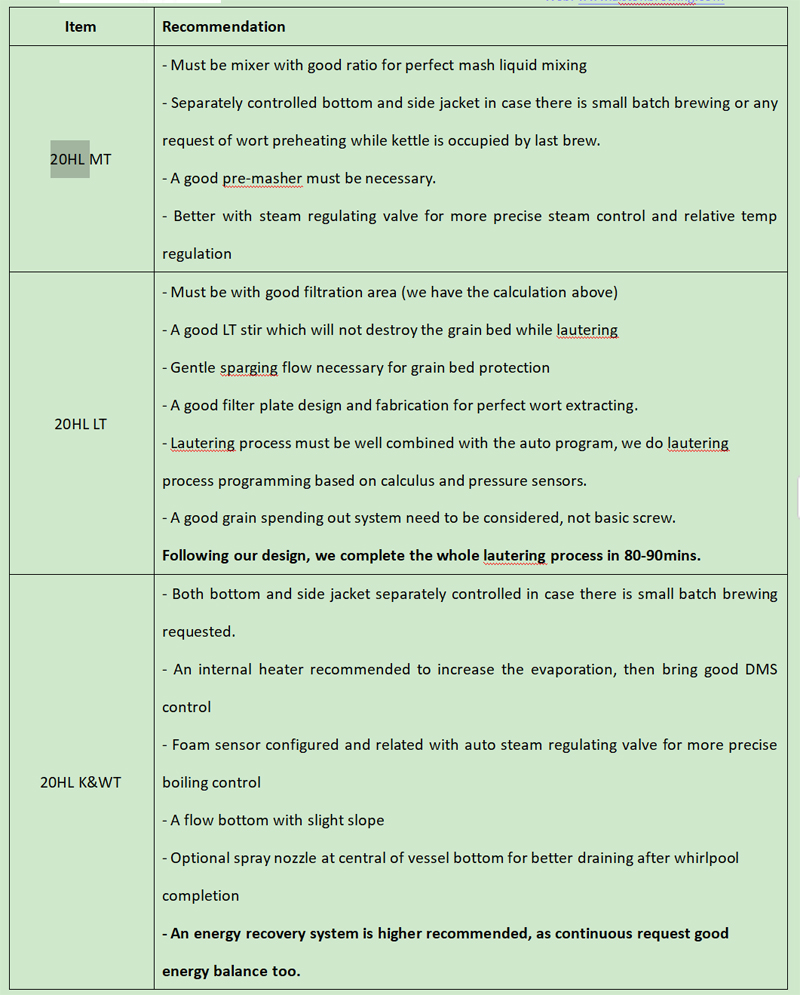

Part Four:Vessel design principle

1.Although the vessels are vessels, I still have some technical recommendation for you to make sure it is a real higher efficient and state-of-art brewhouse, see below:

3.For heat exchanger

- We do calculation on cooling area as the request of your brewing process, eg the wort inlet/outlet temp, wort cooling time etc (we recommend you a PHE of 40HL/H, so you have each brewing wort being cooled in 30mins)

- We have the recommendation of single stage PHE, which is connected with a separate CLT. CLT combined with glycol loop, with the water temp at 3-5 ℃, and prepared for water cooling. The hot water after each time wort cooling flowing back to HLT for new brews.

4.For accessory part:

We have a few notes that we highly recommend for the brewery size and configuration of 20HL

- Brewhouse piping: we offer and recommended to use screw or flange connection, this cost more, but also more stable and safer than TC connection. Alston brew offered the DIN screw connection.

- Steam connection: Be with flange connection. Further more make sure we have to reuse the condensing water from heating.

- Hops doser: You have the option of using the dosing vessel on top of KT, or the hops dosing unit with three vessel together and combined with the whole BH piping works.

- Pneumatic butterfly valves: The quantity follows the brewing request, not only based on liquid transfer from this side to another side. Also we recommend to have proximity switch.

3.Water station:

1.We recommend to have the HLT 3-4 times bigger than brewhouse size. This is based on the request of 3-4 brews per day.

It is important to have enough hot water supply, especially we need water supply at different steps and position while having different brews together.

The hot water pump is recommend to be with 2 sets, firstly for production guarantee while one is under maintaining. Also this is also a way to make sure we have stable enough hot water supply, eg we do water supply for mashing in of the new brew while we still need the sparging water supply of previous brew.

Generally a hot water supply balance is super important for brewhouse efficiency.

2.Further more, we think it is an even better guarantee to have a cold water tank typically used wort cooling, so relatively we suggest to use the single stage heat exchanger. Cold water is combined with glycol loop and water temp is maintained at 3 ℃ for wort cooling. The cold water get hot after wort cooling and transferred back to HLT for the next brew and other use like flushing etc.

3.We do recommend to have cold water tank, which is also based on the concern of cellar temp control. I think the city water temp in Korea is not cold enough, so there can be more times using glycol for wort cooling, while glycol is used mostly for cellar tanks cooling. The risk is when the glycol getting warm after wort cooling, and meanwhile the fermenters need to cooling down the beers, you probably warm the beer, relatively the chiller works under higher pressure too. So generally a CLT helps with good balance between wort and beer cooling. This is even a good guarantee when there is further expansion in brewery.

4.Cellar system:

This is recommended to be further negotiated when client is clear with the exact quantity and volume.

This also depends on the exact percentage of different type of beer.

5.PLC

A perfect software is more important to guarantee the whole system running smoothly and all steps under precise control:

Generally the main control panel should cover more control points, the key points eg CPU etc must be sufficient. The more you want to cover, the more you should invest.

Regarding the software, we have two recommendation;

Brewmaxx from Proleit, we have good relationship with the branch, so the cost can be well controlled

Plantech software from a Chinese company, who is the steam with more than 20 years of background in Proleit.

Instead of an basic touch screen, an industrial computer must be configured for support a good software too.

We are mainly explaining the brewhouse part from this document, as we believe a perfect brewhouse is more important for the whole plant and that is more related with your future brewing.

For others, we hope to have a further conference in China for more detailed communication. We also look forward you coming to visiting and inspecting our facility.

Post time: Nov-16-2024