In order to better serve our customers, according to our company's plan, this year will be a stage of upgrading and upgrading of our equipment.

According to the problems reported by customers, our engineers have finally upgraded and transformed our equipment after half a year of collection, adjustment and hard work.

After the equipment is upgraded, it will improve the brewing efficiency, improve the utilization rate of energy, be more energy-saving, and be more in line with the brewer's usage habits.

The following is the specific upgrade of our equipment:

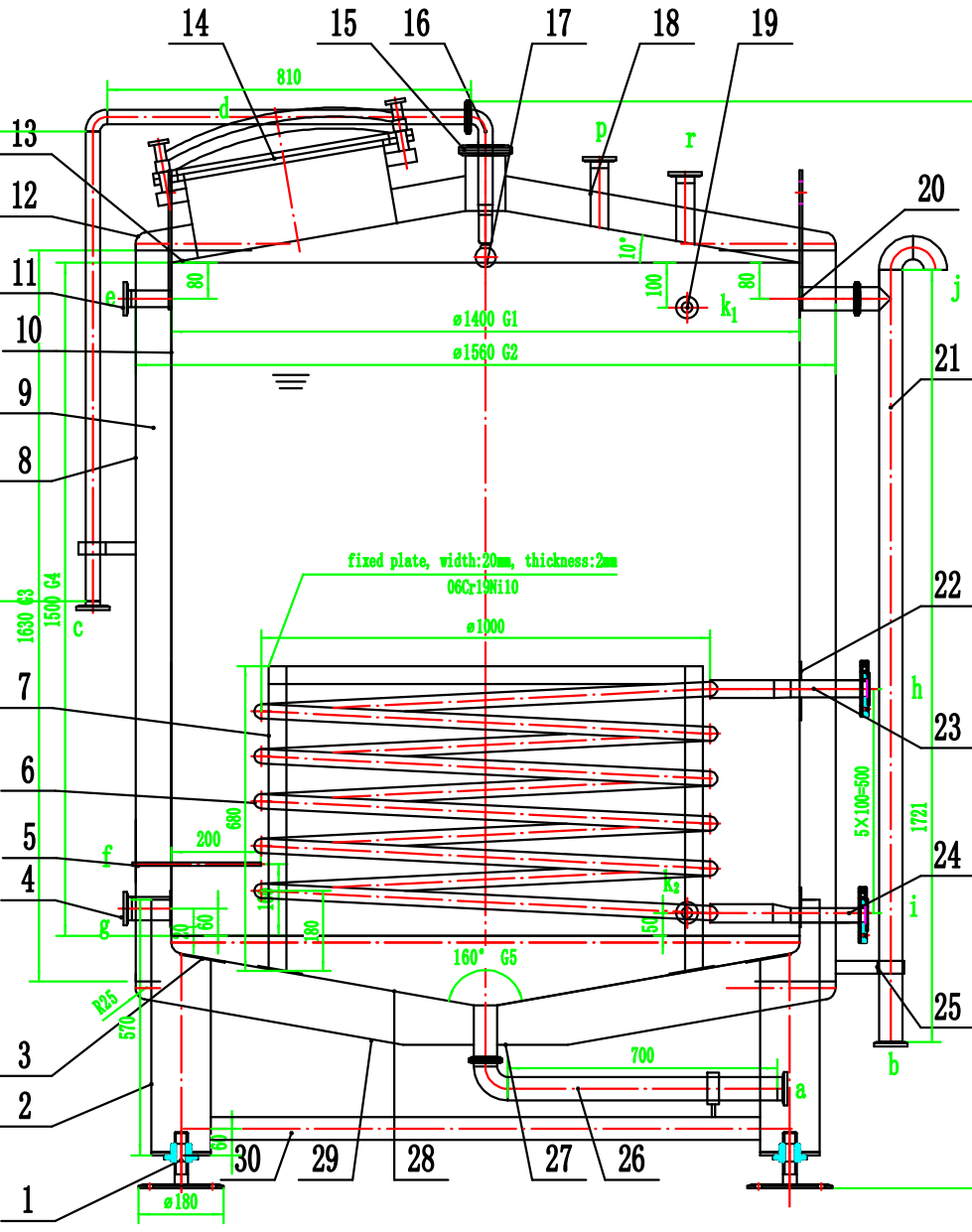

1.Steam coil attached on the heating jacket in mash tun and brewing kettle to make the steam comes more evenly to improve the efficiency of heating.

Steam jacket on bottom of kettle

Steam jacket on cylinder

2.Steam coil inside the hot water tank to improve the heating faster.

3.Two sets of hops filter before wort cooler to filter the hops. The one for use and the other one for spare.

When one filter becomes clogged, you can use the other, especially when making wine continuously.

4.All steam pipes are connected by flanges to avoid the occurrence of steam running, escaping and leaking.

5.Others update on brewhouse

Lauter tank

kettle whirlpool

It is hoped that the upgrade of our equipment can bring more benefits to customers and create more value for the brewery.

Cheers!!

Post time: Jul-26-2022