Brewery Cellar Control Panel: What You Need to Know

1. Definition & Purpose

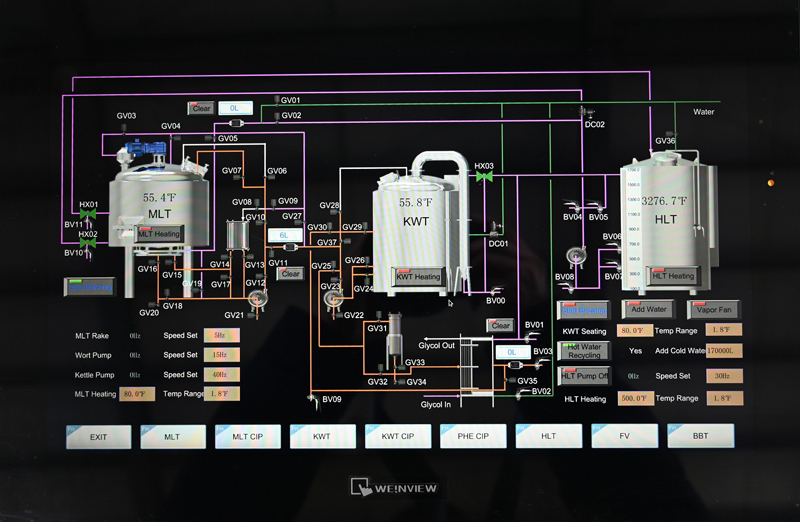

A Brewery Cellar Control Panel is a centralized interface used to monitor and regulate equipment in the fermentation and lagering areas of a brewery. It ensures precise control over critical processes, maintaining product consistency and operational efficiency.

2. Key Components & Functions

2.1 Temperature Control

》Sensors & Actuators: Monitor tank temperatures and adjust glycol cooling systems automatically.

》Zoning: Manage multiple tanks with independent temperature profiles for different beer styles.

2.2 Flow and Transfer Management

》Pumps/Valves: Automate transfers between tanks, kegs, or bright beer tanks.

》Pressure Monitoring: Prevent over-pressurization in fermenters or brite tanks.

2.3 Fermentation Tracking

》Gravity/Pressure Sensors: Track specific gravity (via tilt sensors or refractometers) and CO₂ levels.

》Automated Dosing: Add yeast, nutrients, or finings at scheduled intervals.

2.4 Safety Systems

》Alarms & Emergency Stops: Trigger alerts for leaks, temperature spikes, or pressure failures.

》Sanitization Cycles: Automate CIP (Clean-in-Place) processes for tanks and lines.

2.5 User Interface

》Touchscreen/PLC: Customizable dashboards for real-time data and manual overrides.

》Remote Access: Control operations via mobile/web apps (e.g., IoT-enabled systems).

2.6 Data Integration

》Logging & Reporting: Record batch data for compliance and quality analysis.

》SCADA/MES Integration: Sync with brewery management software for end-to-end tracking.

3. Importance in Brewing

》Consistency: Ensures repeatability in fermentation, critical for brand integrity.

》Efficiency: Reduces manual labor and energy use (e.g., optimized glycol cycles).

》Safety: Mitigates risks of contamination, equipment damage, or hazardous incidents.

》Scalability: Modular designs allow expansion as production grows.

4. Selection Considerations

》Brewery Size: Match panel capacity to tank volume and cellar complexity.

》Customization: Opt for programmable logic controllers (PLCs) to adapt to unique workflows.

》Ease of Use: Prioritize intuitive interfaces for staff training and troubleshooting.

》Vendor Support: Ensure access to technical assistance and software updates.

5. Maintenance Best Practices

》Regular Calibration: Check sensors (temperature, pressure) quarterly.

》Software Updates: Keep firmware/security patches current to prevent vulnerabilities.

》Component Inspections: Clean electrical contacts and test emergency stops annually.

6. Future Trends

》IoT & AI: Predictive maintenance alerts and adaptive fermentation algorithms.

》Energy Optimization: Smart grids integrating renewable energy sources.

》Blockchain Traceability: Immutable batch records for transparency.

Example Use Case

A craft brewery uses the panel to automate a Belgian Saison fermentation:

》Temp starts at 68°F, rising to 80°F over 5 days (controlled via glycol valves).

》Alerts notify staff when final gravity hits 1.008, prompting a transfer to brite tanks.

》Data logs confirm compliance with local alcohol-by-volume (ABV) regulations.

By integrating a cellar control panel, breweries enhance quality, safety, and scalability while reducing operational costs. Always partner with reputable automation specialists for tailored solutions.

Post time: Feb-22-2025