Brewing High Gravity Beers with 5 Key Tips

Brewing high gravity beers offers an exciting challenge for experienced brewers seeking to create bold, flavorful, and robust beers with elevated alcohol content. These beers, characterized by their complex taste profiles and higher original gravity (OG), require precise techniques and meticulous attention to detail.

Mastering specific brewing methods and utilizing the right equipment produces high gravity beers that stand out in quality and taste. Here are five key tips to help you succeed in brewing exceptional high gravity beers.

1.Select High-Quality Ingredients

The quality of your ingredients significantly impacts the flavor, aroma, and overall success of your high gravity beers. Using premium malts, extracts, and sugars ensures that your brew develops the desired complexity and richness associated with high gravity styles.

1.1 Prioritize Fresh Malts and Extracts

Fresh, high-quality malts and extracts provide the essential sugars and flavors necessary for a well-balanced high gravity beer. Specialty malts such as Munich, Vienna, and Crystal malts contribute depth and complexity, enhancing the malt backbone of your brew.

Selecting grains that align with high gravity brewing helps you achieve the desired body and mouthfeel. For instance, using a higher proportion of base malts ensures adequate enzymatic activity to convert starches into fermentable sugars in gravity worts.

1.2 Optimize Sugar Additions

Adjunct sugars play a vital role in increasing alcohol content without overly affecting the beer’s body or introducing unwanted sweetness. Simple sugars like dextrose (corn sugar) and sucrose (table sugar) are fully fermentable and can boost the gravity efficiently. However, it’s essential to use them judiciously to prevent thinning or off-flavors. Incorporate this sugar tip for brewing high gravity beers: add sugars during the boil or even during fermentation to give the yeast a gradual increase in fermentables. This change can improve attenuation and overall beer stability.

2.Pitch Enough Yeast for Successful Fermentation

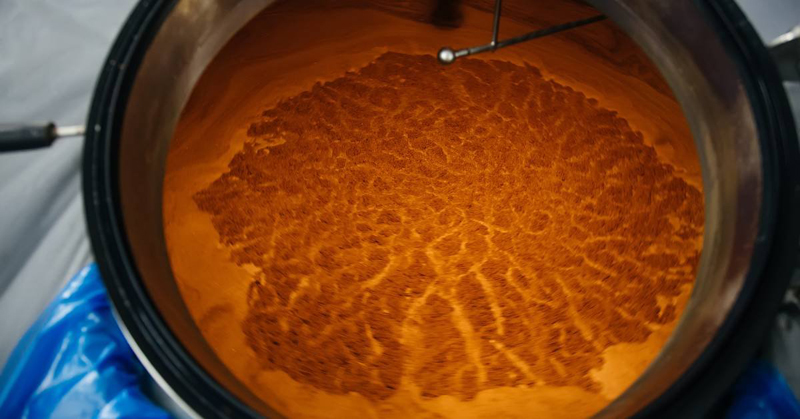

A large brewing vat containing fermenting yeast and other ingredients inside of a stainless steel beer wort.

A healthy and vigorous fermentation is critical when brewing high gravity beers. Yeast must be abundant and robust enough to handle the high sugar concentration in the wort, which can be stressful for the cells. Pitching an adequate amount of yeast produces a complete fermentation and prevents issues such as off-flavors or stuck fermentation.

2.1 Use a Yeast Starter or Propagation System

Creating a yeast starter or using a propagation system significantly increases the yeast cell count, preparing them for the demanding environment of high gravity wort. A yeast starter involves growing yeast in a small volume of wort before pitching it into the main batch, which builds the yeast population and vitality.

For efficient yeast management, consider using a yeast brink. If you’re looking for a yeast brink for sale, Craftmaster Stainless offers reliable yeast management tools that facilitate yeast propagation and storage. Utilizing such equipment ensures that your yeast is healthy and ready to ferment high gravity worts effectively.

2.2 Supplement Yeast Nutrients

Yeast nutrients provide essential vitamins, minerals, and amino acids that support yeast health and fermentation performance. High gravity worts can be deficient in certain nutrients due to their composition.

Adding yeast nutrients like diammonium phosphate (DAP) or yeast energizers prevents fermentation problems such as sluggish or stuck fermentation. Select nutrients based on your beer style and the specific needs of your yeast strain to ensure optimal fermentation.

3.Control Fermentation Temperature

Maintaining a stable fermentation temperature is crucial for producing high-quality high gravity beers. Temperature fluctuations can stress yeast and produce off-flavors, compromising the beer’s overall profile. You ensure that the yeast performs optimally, resulting in a cleaner and more refined beer by controlling the fermentation temperature.

3.1 Use Temperature-Controlled Equipment

Investing in temperature-controlled fermentation equipment allows you to maintain consistent temperatures throughout the fermentation process. Fermentation chambers, glycol cooling systems, and temperature controllers are effective tools for regulating fermentation conditions.

Craftmaster Stainless provides high-quality temperature-regulating brewing equipment. Equipment like stainless steel fermenters with integrated cooling systems helps brewers maintain the ideal environment for yeast activity. Using such equipment reduces the risk of temperature-related fermentation issues and contributes to the production of superior high gravity beers.

3.2 Monitor and Adjust Temperatures Regularly

Regular monitoring of fermentation temperatures enables you to detect and correct any deviations promptly. Use reliable thermometers or digital temperature sensors to keep an eye on the fermentation environment. A key tip for brewing high gravity beers: set up alerts or use automated systems to maintain temperatures and adjust as necessary. Aim to prevent fluctuations that could impact yeast performance and beer quality.

4.Monitor and Adjust pH Levels for Balance

A man smiling in an apron and hard hat holding a tablet while standing next to stainless steel brewing tanks.

The pH level of your wort and beer significantly influences yeast activity, enzymatic reactions, and the final flavor profile. Maintaining the pH within the optimal range promotes healthy fermentation and enhances the stability and taste of your high gravity beer.

4.1 Use pH Test Strips or Meters.

Accurate measurement of pH is essential for making necessary adjustments during brewing and fermentation. Use reliable pH test strips or digital pH meters to monitor the pH levels at various stages, such as during the mash, boil, and fermentation. Regular testing allows you to identify any deviations from the ideal pH range and take corrective action promptly.

4.2 Balance pH With Brewing Salts

You can adjust and balance the pH by adding brewing salts or acids. For example, adding calcium carbonate (chalk) can raise the pH, while adding lactic acid or phosphoric acid can lower it.

Brewing salts like gypsum (calcium sulfate) and calcium chloride not only help in pH adjustment but also enhance the beer’s flavor profile by accentuating maltiness or hop bitterness. Understanding the impact of these additives on both pH and taste allows you to fine-tune your high gravity beer to achieve the desired balance and complexity.

5.Practice Patience and Precision

Brewing high gravity beers requires meticulous attention to detail and a willingness to invest time and effort. Patience and precision at every stage of the brewing process contribute significantly to the success of your brew.

5.1 Plan and Document Your Process

Thorough planning and documentation help you control variables and replicate successful brews. Keep detailed records of your recipes, brewing steps, fermentation parameters, and any adjustments made along the way. Planning and documenting enable you to analyze the results and make informed decisions for future batches, continually improving your high gravity brewing techniques.

5.2 Allow Sufficient Conditioning Time

High gravity beers often benefit from extended conditioning periods. Aging allows the flavors to meld and mature, smoothing out any harsh alcohol notes and developing greater complexity. Prepare to cellar your high gravity beer for several months or even longer, depending on the style. Patience during the conditioning phase can transform a good beer into an exceptional one.

Post time: Dec-21-2024