Where are flow meters used in Brewery?

Flow meters are essential in modern breweries, ensuring precision, efficiency, and consistency throughout the brewing process. These instruments are designed to measure and control the flow of liquids and gases, making them indispensable in a brewery’s operations. From water intake to the carbonation of the final product, flow meters help monitor critical stages like wort transfer, ingredient dosing, fermentation, and cleaning. Accurate measurement allows brewers to maintain product quality across batches, optimize resource usage, and minimize waste. Additionally, flow meters contribute to sustainability by enabling breweries to track water consumption and control CO2 usage. Various types available—such as magnetic, Coriolis, and ultrasonic flow meters—offer unique advantages for specific brewing tasks. As breweries increasingly adopt automation and data-driven processes, flow meters play a pivotal role in achieving consistency, safety, and regulatory compliance. This article explores the many functions flow meters serve in breweries and how they enhance overall production efficiency.

I.Understanding Flow Meters

1.1 What is a Flow Meter?

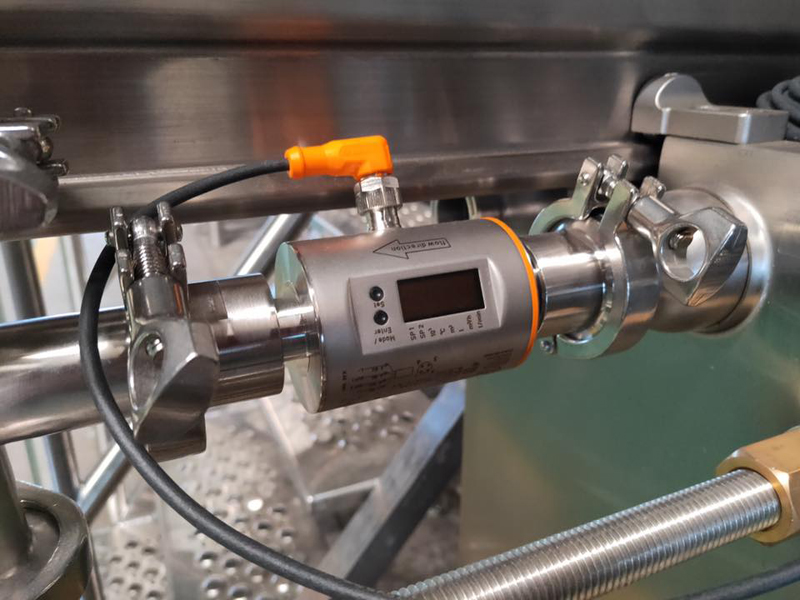

A flow meter is a device used to measure the flow rate of liquids or gases through a pipe or system, expressed in terms of volume (such as liters per minute) or mass (like kilograms per hour). In the brewing industry, flow meters are used to monitor and control the flow of water, wort, beer, and gases such as CO2. Precision in flow measurement ensures that each step in the brewing process is optimized, from ingredient mixing to cleaning procedures. This accuracy allows breweries to maintain consistent product quality, improve efficiency, and minimize waste. Flow meters come in various types, including magnetic, Coriolis, ultrasonic, and turbine flow meters, each suited to specific applications within the brewing process.

1.2 How Flow Meters Work

Flow meters function by detecting the velocity, pressure, or displacement of the liquid or gas passing through them and converting these readings into flow rate data. The working principle varies depending on the type of meter:

-Magnetic Flow Meters: These generate a magnetic field and measure the voltage induced by the movement of conductive liquids, such as wort or beer, through the field. The voltage is proportional to the flow rate.

-Coriolis Flow Meters: These rely on the Coriolis effect, where the deflection of a vibrating tube corresponds to the mass flow of liquid. These meters are ideal for measuring viscous ingredients or high-density fluids like yeast slurry.

-Ultrasonic Flow Meters: Using sound waves, these meters measure the time or frequency shift of sound waves traveling through the liquid, providing a non-contact method for precise flow measurement.

-Turbine Flow Meters: A mechanical rotor spins as liquid flows through, with the rotational speed correlating to the flow rate.

By measuring the rate of flow, breweries gain real-time insight into production processes, allowing them to control ingredient additions, monitor CO2 infusion during carbonation, and manage water and cleaning solutions efficiently. Flow meters not only streamline operations but also ensure consistent batch quality and compliance with industry standards.

II.Importance of Flow Meters in Breweries

Flow meters are indispensable in breweries, ensuring precision, consistency, and efficiency across various production stages. They help brewers maintain control over water, wort, ingredients, carbonation, and cleaning processes—key factors in achieving product quality and operational efficiency. Below are the specific areas where flow meters play a critical role.

2.1 Accurate Measurement and Control of Water Usage

Water is the primary ingredient in beer, and its quality and quantity directly affect the final product. Flow meters allow breweries to precisely control water usage during brewing, ensuring the correct amount is added to each batch. Even small variations can alter the beer’s flavor, texture, or alcohol content. Additionally, flow meters help optimize water management, contributing to sustainability by reducing unnecessary consumption and waste.

2.2 Managing Wort Flow

During brewing, wort—the liquid extracted from the mashing process—must be transferred smoothly from the mash tun to the brew kettle and then into fermentation tanks. Flow meters monitor the flow rate of wort to prevent disruptions or contamination. Consistent flow ensures that brewing schedules stay on track, reduces the risk of over- or under-aeration, and preserves the integrity of the wort’s flavor profile, ultimately leading to a higher-quality beer.

2.3 Controlling Ingredient Additions

Flow meters help manage the precise addition of ingredients such as hops, malt extracts, and flavorings at specific times. Since brewing relies on accuracy to achieve consistency across batches, these meters ensure that the right quantity is added, preventing overuse or underuse. For breweries experimenting with new recipes, flow meters provide valuable data for scaling ingredient additions from small to large production runs while maintaining quality.

2.4 Carbonation and CO2 Flow Control

Carbonation can help create the right taste and appearance of beer. Flow meters are used to monitor and control the flow of carbon dioxide (CO2) during carbonation to ensure optimal fizz and prevent under or over-carbonation. Accurate CO2 measurement keeps every batch of beer consistent. Furthermore, precise CO2 control helps breweries reduce gas consumption, lowering costs and minimizing environmental impact.

2.5 Cleaning and Sanitization

Maintaining a hygienic production environment is crucial for breweries, as any contamination can spoil beer or damage equipment. Flow meters ensure that the correct amount of cleaning agents and sanitizers flows through the system during cleaning cycles. They help verify that every part of the equipment—such as fermentation tanks, pipes, and brew kettles—is thoroughly cleaned. Accurate measurement also prevents waste of chemicals and ensures that the brewery complies with health and safety regulations, reducing the risk of contamination.

In each of these areas, flow meters help breweries operate efficiently, meet regulatory requirements, and maintain product consistency. Alston brew provides brewery equipment that integrates reliable flow meters to optimize production processes, ensuring brewers have the tools they need for sustainable, high-quality brewing.

III. Applications of Flow Meters in Different Stages of Brewing

Flow meters play a vital role in various stages of beer production, ensuring that processes run smoothly, efficiently, and consistently. Their ability to accurately monitor and control fluid flow helps breweries maintain product quality, optimize operations, and minimize waste. Below are the key applications of flow meters in different stages of brewing.

3.1 Mashing and Lautering

In the mashing process, water is mixed with milled malt to extract fermentable sugars, creating a mash. Accurate control of water flow into the mash tun is crucial, as it ensures the proper grain-to-water ratio, which directly affects the sugar extraction and beer quality. Flow meters also regulate the hot water flow used during lautering, where the wort is separated from the spent grain.

-Flow Meter Role: Ensure precise water addition during mashing, and control sparge water flow for efficient wort extraction.

-Impact: Optimizes sugar yield, improves wort clarity, and ensures consistency across batches.

3.2 Boiling and Hopping

After lautering, the wort is transferred to the brew kettle for boiling. This stage sterilizes the wort, removes unwanted compounds, and concentrates the flavors. During boiling, hops are added at specific intervals to impart bitterness, aroma, and flavor to the beer.

-Flow Meter Role: Monitor the transfer of wort into the brew kettle, and control the flow of hop extracts or hop additions.

-Impact: Maintains consistency in bitterness and flavor by ensuring precise hop additions and effective boiling times.

3.3 Fermentation

During fermentation, yeast converts the sugars in the wort into alcohol and carbon dioxide (CO2), creating beer. The wort must be transferred smoothly to the fermentation tank to avoid contamination or aeration issues. In addition, CO2 produced during fermentation must be properly monitored and controlled.

-Flow Meter Role: Regulate wort flow into fermentation tanks, monitor and control the CO2 flow for venting or carbonation purposes.

-Impact: Ensures optimal fermentation conditions, prevents contamination, and maintains product quality.

3.4 Packaging

In the final stage, the beer is packaged into bottles, cans, or kegs. Flow meters help ensure that each container is filled with the correct volume of beer, reducing waste and maintaining consistency. Additionally, precise monitoring of CO2 during carbonation ensures that the beer has the right amount of fizz.

-Flow Meter Role: Measure beer flow during filling, and monitor CO2 flow to maintain consistent carbonation levels.

-Impact: Minimizes product loss, ensures accurate filling and enhances customer satisfaction with consistent carbonation and taste.

Flow meters are essential at every step of the brewing process, helping brewers achieve consistency, quality, and efficiency. Alston brew provides breweries with high-quality equipment, including flow meters tailored for various brewing applications. By integrating these meters into their systems, breweries can ensure smooth operations, meet regulatory standards and deliver excellent beer to their customers.

IV. Advantages of Using Flow Meters in Breweries

Flow meters are invaluable tools in breweries, providing precision, control, and efficiency at every stage of the brewing process. By integrating flow meters, breweries can optimize their operations, reduce costs, and ensure product quality. Below are the key advantages of using flow meters in breweries.

4.1 Accuracy and Consistency

Brewing is a meticulous process where even minor deviations can impact the final product’s flavor, appearance, and quality. Flow meters provide precise control over the volume of liquids and gases used during each stage, from water intake to ingredient additions and carbonation.

-Impact: Flow meters ensure each batch meets the same quality standards, providing customers with consistent beer flavor and texture.

-Example: Accurate measurement of hop extracts ensures bitterness remains consistent across batches.

4.2 Improved Process Efficiency

By accurately controlling the flow of liquids and gases, flow meters reduce downtime and bottlenecks. Flow meters allow brewers to maintain optimal production speeds, ensuring smooth transfers between brewing stages, such as wort transfer or beer filling, without delays.

-Impact: Optimizes production schedules, reduces time between brewing steps, and maximizes equipment utilization.

-Example: Real-time monitoring of wort flow helps prevent interruptions and keeps the process on schedule.

4.3 Reduction of Waste and Cost Savings

Precise flow measurement helps breweries minimize the overuse of water, CO2, ingredients, and cleaning agents, preventing waste and lowering operational costs. Flow meters also reduce product loss during packaging by ensuring accurate fills.

-Impact: Supports sustainable practices by reducing water and resource consumption while lowering operating expenses.

-Example: Accurate CO2 control during carbonation ensures minimal gas usage without compromising beer quality.

4.4 Real-Time Monitoring and Automation

Modern breweries are adopting automation to improve efficiency and consistency. Many flow meters are equipped with data logging and remote monitoring capabilities, allowing brewers to oversee operations from a central control system. This enables quick adjustments based on real-time data, reducing the need for manual interventions.

-Impact: Enhances productivity by automating routine tasks and allowing for quick responses to potential issues.

-Example: Automated wort flow monitoring prevents over-aeration by adjusting flow rates as needed in real-time.

4.5 Regulatory Compliance

Breweries must comply with strict health, safety, and environmental regulations. Flow meters help ensure that cleaning and sanitization processes are effective by verifying that the proper amount of cleaning agents is used. They also ensure accurate CO2 usage, aiding in environmental compliance by minimizing emissions and waste.

-Impact: Reduces the risk of contamination, ensures safe production practices, and helps breweries meet environmental and safety standards.

-Example: Accurate flow monitoring during tank cleaning ensures compliance with food safety regulations.

Flow meters play a critical role in maintaining product quality, optimizing processes, reducing costs, and ensuring compliance.

Summary

Flow meters are essential tools in breweries, ensuring precision, consistency, and efficiency across all stages of production. From accurately measuring water usage during mashing and controlling wort flow to managing ingredient additions and regulating CO2 during carbonation, flow meters play a vital role in maintaining product quality. They also monitor cleaning and sanitization processes, ensuring hygiene standards are met while minimizing waste.

Get Turnkey Brewery Solutions

At Alston brew, we provide comprehensive brewery solutions designed to meet the needs of both small craft breweries and large commercial operations. Flow meters are integral components of our turnkey brewery systems, ensuring precise control over liquid and gas flows at every stage of brewing. Whether it’s accurate water measurement during mashing, regulating CO2 flow for carbonation, or monitoring ingredient additions, our flow meters help brewers maintain consistency and optimize efficiency.

With Alston brew’s turnkey solutions, breweries benefit from fully integrated equipment tailored to their production goals. Our expert team provides personalized consultation, helping you select the right flow meters for your operations. We also offer seamless installation, calibration, and maintenance services, ensuring your brewing processes run smoothly from day one.

As a professional brewery equipment provider, Alston brew is committed to delivering reliable, efficient, and sustainable solutions. Partner with us to equip your brewery with advanced flow meter technology and take your brewing operations to the next level.

Post time: Jan-04-2025