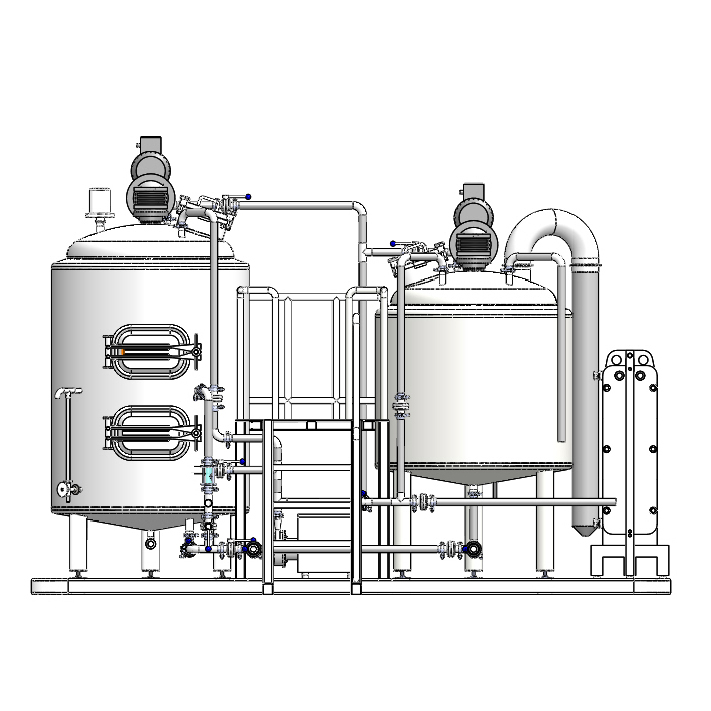

PriceList for Industrial Beer Brewing Equipment - 500L Micro brewery turnkey system – Alston Detail:

General description

Capacity: 5HL 10HL 20HL Or 5BBL 10BBL 15BBL or customized

Heating method: Steam (recommended), Direct fire, Electric element.

Efficiency: Max 4 Brews per day

According to your brewing process and usage habits, we can provide you traditional 3 vessel: mash tun, lauter tank, kettle&whirlpool, 2 vessel: mash lauter tank, kettle whirlpool tank, 3 vessel combination system: mash kettle tun, lauter at upper part, whirlpool at lower part.

Brewhouse is designed and fabricated as the exact brewing process request from client and the local requirement. Tanks size designed as exact beer plato / gravity from client. The goal is helping client with easy brewing operation, making the whole brewhouse setup more suitable for right recipe , increasing the efficiency and lowering the energy cost etc.

Making a brewery is longer term operation, our wish is helping you find the value behind our price, and develop the balance between income and investments.

Features

● Higher wort extract

● Lower energy cost and material consumption

● Well adjusted temp and water blending unit for better grain and water mixing

● Higher efficiency steam jacket to increase heating efficiency and lower energy consumption

● Special tank and piping construction to avoid the wort aeration problem and decrease the material lost

● Special designed steam condensing unit, with both steam condensing and water heating function

● Adopting advanced world famouse brand components to ensure the smoothly running;

● Support different heating way, steam, direct fire and electric, depending on site and local utility costs.

● High-quality stainless steel material 304 or 316 and exquisite appearance.

● Brewing vessel and fermentation tanks are tested prior to shipment to avoid on-site repairs, guarantee uninterrupted startup and assured vessel performance.

Standard setup

| No. | Item | Equipment | Specifications |

| 1 | malt milling system | Malt miller machine | The entire grain milling unit from outside silo to inside mill, receptacle, premasher and so on |

| Grist case(optional) | |||

| Flex auger(optional) | 1.Conveys grist from malt mill to grist case;2.Inside stainless screw, outside PPR protection tube;3.Associated motor with frequency conversion | ||

| 2 | Mash system | Mash tank, | 1.Machinical Agitation: With VFD control, at the top horizontal motor with seal.2.Steam venting chimney with anti backflow pipe.3.Condensate recycle to hot water tank. |

| Lauter tank | Function: lauter, filter the wort.1.Sparging pipe for grain washing with TC connection.2.Wort collecting pipe and back washing device to cleaning false bottom.3.Mechanical Raker: VFD control, gear motor on the top.

4.Spent grain:Automatic raker device, Grain removing plate with reverse, forward is raker, reverse is grain out. 5.Milled false bottom: 0.7mm distance, diameter designed suitable for the lauter tun, with dense supporting leg, detachable handle. 6.Wort circulation inlet TC on top with elbow and mash inlet upon false bottom on side wall. 7.Side mounted spent grain port . 8.With discharge hole, thermometer PT100 and necessary valves and fittings. |

||

| Boiling Whirlpool tank | 1.Whirlpool tangent pumped at 1/3height of the tank2.Steam venting chimney with anti backflow pipe.3.Condensate recycle to hot water tank. | ||

| Hot water tank (optional) | 1.Steam Jacket heating/direct gas fired heating/electric heating2.Sight gauge for water level3.With SS HLT pump with variable speed control | ||

| Mash/wort/hot water pump | Transfer the wort and water to each tank with frequency control. | ||

| Operation pipes | 1.Material: SS304 sanitary pipes.2.Sanitary stainless steel valve and pipeline, Easy to operate and reasonable in design;3.Wort inlet at side of tank to reduce the oxygen. | ||

| Plate heat exchanger | Function: wort cooling.1.Two stage and six flow, hot wort to cold wort, tap water to hot water, glycol water recycle.2.Design Structure: Suspension type, screw material is SUS304, nut material is brass, easy disassembled for cleaning.3. Stainless steel 304 material

4.Design pressure:1.0 Mpa; 5.Working temperature:170°C. 6.Tri-clamp quick-installed. |

||

| 3 | Fermenting system(Celler) | Beer fermenters | Jacketed Conical fermentation tank for beer cooling, fermenting and storage.1.All AISI-304 Stainless Steel Construction2.Jacketed & Insulated3.Dual Zone Dimple Cooling Jacket

4.Dish Top & 60° Conical Bottom 5. Stainless Steel Legs with Leveling Ports 6.Top Manway or Side Shadow less Manway 7.With Racking arm, Discharge Port, CIP Arm and Spray Ball, Sample Valve, Shock proof Pressure Gauge, Safety Valve, Thermowell and Pressure regulator valve. |

| 4 | Bright beer system | Bright beer tanks (optional) Yeast adding tank Accessories, such as sample valve, pressure gauge, safety valve and so on |

Beer maturation/conditioning /serving/filtered beer receiving.1.All AISI-304 Stainless Steel Construction2.Jacketed & Insulated3.Dual Zone Dimple Cooling Jacket

4.Dish Top & 140° Conical Bottom 5.Stainless Steel Legs with Leveling Ports 6.Top Manway or Side Shadow less Manway 7.With Rotating Racking arm, Discharge port, CIP Arm and Spray Ball, Sample Valve, Shock proof Pressure Gauge, Safety Valve, Pressure regulator valve, Thermowell, Level sight, Carbonation stone. |

| 5 | Cooling system | Ice water tank | 1.Insulated conical top and sloped bottom2.Liquid level sight tube for water level3.Rotating CIP spray ball |

| Refrigerating unit Ice water pump |

Assembly unit, wind cooling, enviromental refrigerant: R404a or R407c, compressor and electrical part meet UL/CUL/CE certification. | ||

| 6 | CIP cleaning system | disinfection tank & alkali tank &cleaning pump etc. | 1).Caustic tank: Elctric heating element inside, with anti-dry device for safety.2).Sterilization tank: Stainless steel vessel.3).Control and pump:Portable sanitary CIP pump, SS cart and controller. |

| 7 | Controller | Control system: | PLC automatic and semi-automatic, the elements brand include Schneider, Delixi, Siemens and so on. |

Product detail pictures:

Related Product Guide:

Sticking to your belief of "Creating solutions of high quality and generating buddies with people from all around the world", we always put the fascination of customers to start with for PriceList for Industrial Beer Brewing Equipment - 500L Micro brewery turnkey system – Alston, The product will supply to all over the world, such as: French, Auckland, Amsterdam, Our company offers the full range from pre-sales to after-sales service, from product development to audit the use of maintenance, based on strong technical strength, superior product performance, reasonable prices and perfect service, we'll continue to develop, to deliver the high-quality items and services, and promote lasting cooperation with our customers, common development and create a better future.

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!