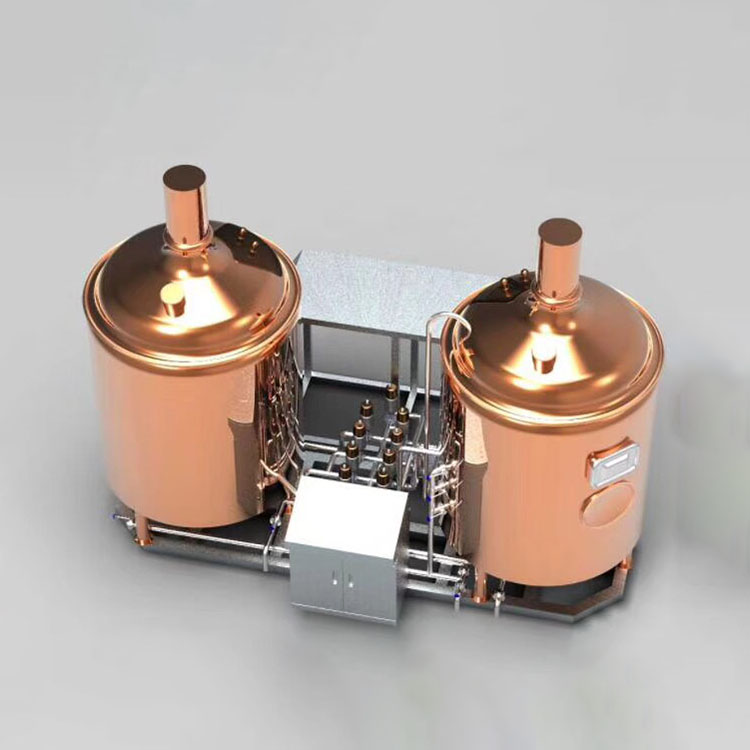

Wholesale Beer Manufacturing Equipment - Copper Brewhouse Micro Brewery system – Alston Detail:

General description

Capacity: 5HL, 10HL, 15HL, 20HL Or 5BBL 7BBL 10BBL 15BBL or customized.

Material: Red copper, SUS304(inside).

Heating method: Electric / steam / gas fired.

Efficiency: 1-3 Brews per day.

Brewhouse unit:

1. Mash tun/Lauter tank+kettle/whirlpool.

2. Mash/kettle tank+upper Lauter tank/Whirlpool.

3. Mash/kettle/whirlpool+Lauter tank.

The brewhouse following exact building requirement and the exact beer gravity from different investors. Piping works for the brewhouse is easier but more professional to make sure there is less wasting and everything following customers brewing recipe requirement.

Basic configuration

● Mash / lauter tun with top or bottom blade stir, counter washing and wort collect coil.

● Kettle / whirlpool with tangent inlet, electric heater inside tank, steam jacket or gas chamber underneath.

● Support fittings: double / single stage plate cooler, piping strainer, grist hydrator, wort sink etc.

● Standard brewhouse platform or customized.

● All pump & Stir with VFD.

● With hot water tank configured for sparging and mashing in etc.

● Valves to be manual butterfly one or pneumatic.

● Piping connection to be TC or DIN.

● Hot water tank to be 2-3 times bigger for mashing, sparging and cleaning.

Features

● Looks luxurious on the outside, nicely decorated bar and restaurant

● Reasonable water blending unit for temp and water amount control.

● Well sized tank diameter to guarantee right filtration are for wort extract.

● Lower energy cost and material consumption.

● Wort grant creating more buffer during lautering.

● Wort dam in kettle for clearance wort.

● Special tank and piping construction to avoid the wort aeration problem and decrease the material lost.

● Whole brewhouse unit can be installed on frame.

Product detail pictures:

Related Product Guide:

Gaining purchaser gratification is our firm's intention eternally. We will make wonderful endeavours to build new and top-quality merchandise, satisfy your exclusive needs and provide you with pre-sale, on-sale and after-sale products and services for Wholesale Beer Manufacturing Equipment - Copper Brewhouse Micro Brewery system – Alston, The product will supply to all over the world, such as: Ukraine, St. Petersburg, Florida, With many years good service and development, we've a professional international trade sales team. Our products have exported to North America, Europe, Japan, Korea, Australia, New Zealand, Russia and other countries. Looking forward to build up a good and long term cooperation with you in coming future!

Problems can be quickly and effectively resolved, it is worth to be trust and working together.